| |||||||

Loading

|

| | LinkBack | Thread Tools | Display Modes |

| |||||||

|

| | LinkBack | Thread Tools | Display Modes |

| | #1 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

|

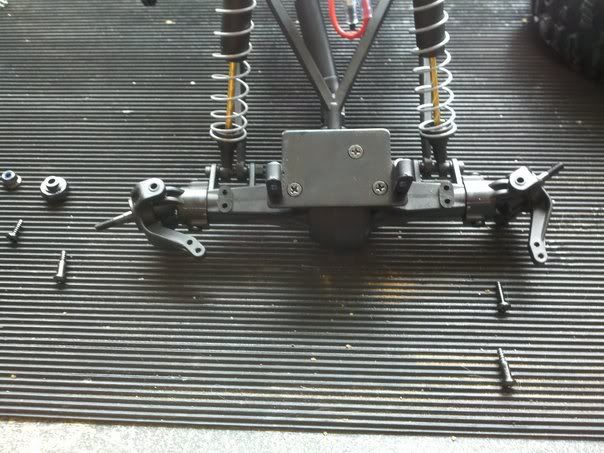

started out by picking up a first gen ax10 used once for $100.  Awesome stock steering.  Got some new toys  tear down  Vanquish high steers LD BTA kit with the factory 3 link.  Almost done, just need some m3 screws of the 16mm variety and to jerry rig the pitman arm/drag link till i can get my CPE servo in it. hopefully the stock servo doesnt hit the spring....  Thats it for now. CPE serv 4 servo on its way with a tm br-xl following close behind. EDIT 8/11/11: Updated Parts list: Fastback II Chassis Black running 4 1/8 front lower link lengths (they suggest 4 1/4) and 5 1/16 rear lower link length Crawford Performance Ser4 servo with long robitronics servo horn (it hits the LD BTA cross bar) White dot rovers with vanquish SLW V3's & some type of foam GT3B TX/RX Holmes Hobbies Torquemaster BR-XL 27T axial/ 35T Integy V11/ Older Holmes Hobbies Handwound 540 PRO 45T one with a p94 hood the other has lay down brushes. MIP Short & long driveshaft Inkdaddy66 RAMROD steel axle tubes (coming soon) Inkdaddy66 custom C-hubs made form Tool steel Robinson Racing Steel outdrive gear Robinson racing 32 pitch 14T steel pinion gear Last edited by Crawford; 08-11-2011 at 10:59 PM. |

| |  |

| Sponsored Links | |

| | #2 |

| Quarry Creeper Join Date: Feb 2011 Location: Vancouver, WA

Posts: 423

|

Looking good, get rid of that servo saver ASAP. If you have the original parts tree there is a plastic arm that would be better than the servo saver or better yet an aluminum arm.

|

| |  |

| | #3 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

thanks for the tip! Last edited by Crawford; 07-12-2011 at 11:11 PM. | |

| |  |

| | #4 |

| Quarry Creeper Join Date: Feb 2011 Location: Vancouver, WA

Posts: 423

|

Another piece of advice is to move your lower links inboard and get/make a 4 link plate for the rear. In order to reduce torque twist try to triangulate you lower links as much as possible. This can be accomplished by moving your shocks out and also moving your lower links out on the axle while moving your lower links in on the skid plate. I also noticed that you are running the 27T motor. You may want to consider a higher turn motor. a 35T would be ideal but a 45Tor 55T would be better suited for crawling. I see that you are going with a BR-XL ESC. It would work great on 3S lipo coupled with a 35T motor. |

| |  |

| | #5 |

| RCC Addict Join Date: Oct 2009 Location: San Francisco

Posts: 1,927

|

Get a D-link from Underground Crawlers for the rear, it's the ultimate 4-link plate! Torque twist fighting... D-link, longer upper links and better chassis geometry helps! The stock one only goes so far Keep up the good work on there! |

| |  |

| | #6 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

just too much wheel spin not enough torque? to be honest i wasn't planning 4 linking the rear. at least not yet even though i bought enough 1/4 brake line and double the ammount of all-thread i would need. might have to go get another packet of revo ends from rpp hobby. or maybe try the jato's instead? I'll check out the d-link thanks | |

| |  |

| | #7 |

| Rock Crawler Join Date: Apr 2010 Location: Central FL

Posts: 509

|

i use revo ends all around on my fastback. definitely 4-link the rear - you can either make a custom plate, or get the Bender 4link plate or UGC's Dlink (I personally like the dlink the best). 27t geared 14/87 might be ok, but the stock motor just doesn't have the same grunt that even a machine wound 35t from HH has. (btw if you are planning on a brxl, and haven't purchased yet, just get the combo - the motor ends up practically free) |

| |  |

| | #8 | |

| Rock Crawler Join Date: Jun 2008 Location: Grants Pass OREGON!

Posts: 509

| Quote:

All awesome advice! Can't go wrong with a HH combo. | |

| |  |

| | #9 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

|

just thought I would add, 255gr .45 cal lead bullets work great for wheel weights, just stuff them between the foam and the rim. put in just under 4 oz in each tire. used 8 in each.

|

| |  |

| | #10 | |

| Rock Crawler Join Date: Jun 2008 Location: Grants Pass OREGON!

Posts: 509

| Quote:

oof,imagine if you smacked a rock in just the right way to lite one off. and is that cheaper then sticky wheel weights? would rather have the rounds in my gun then in my crawler? but then again cali has some stupid gun laws these days,might be a real traveling with your ammo law. | |

| |  |

| | #11 |

| I wanna be Dave Join Date: Jun 2008 Location: Vermont

Posts: 2,016

|

I'm fairly confident he meant the bullets themselves, not a whole cartridge.  I think stick on wheel weights are the easiest to work with and get accurate account of weight on each rim. |

| |  |

| | #12 | ||

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

Quote:

Update: 4 days of r/c wheeling while up at slick rock by utica resevoir netted me a ton of scratches, lots of dirt/dust, quite a few flip overs, a popped driver rear shock which was promptly refilled with PB blaster (which caused my O-ring to swell and wouldn't go back in), stripped the factory servo horn, swapped on a friends servo saver There is some good news. my br-xl came in friday so did my new servo (WOO I CAN STEER NOW!!!!) installing both tomorrow, then seeing if I fried the motor or the esc or both or what..... Last edited by Crawford; 08-11-2011 at 10:41 PM. | ||

| |  |

| | #13 |

| Quarry Creeper Join Date: May 2011 Location: Japan

Posts: 235

| |

| |  |

| | #14 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

|

got the br-xl in, AWESOME! Has anyone used the JD BTA kit with a long robitronics servo horn??? Last edited by Crawford; 07-18-2011 at 01:43 PM. |

| |  |

| | #15 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

|  Had a lot of fun at P.g. with it, tires bind up A LOT, dang near too much grip and the torque twist is killing me in some spots, but in others is quite helpful and i'm learning to use it to my advantage. The home made rear high clearance links helped in a few spots, enough to make them worthwile, however they screwed my suspension geometry up pretty bad. Reason for brakeline on one and not fully on the other was an experiment. |

| |  |

| | #16 |

| RCC Addict Join Date: Jan 2009 Location: Crawlifornia

Posts: 1,941

| |

| |  |

| | #17 |

| RCC Addict Join Date: Jan 2009 Location: Crawlifornia

Posts: 1,941

|

No in reality tho. Inboard ur lower links at the chassis either right inside using the stock skid or with a EEM double triangulation skid. And 4 link the rear. and mirror the trans then flip the motor to the front passenger side. Then reconnect the shocks.  |

| |  |

| | #18 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

Man down! Crawford performance engineering servo, 2 uses.... Edit, before someone gets any funny ideas, the aluminum battery plate only has 4 uses on it  | |

| |  |

| | #19 |

| Rock Stacker Join Date: May 2011 Location: san diego

Posts: 60

|

Just my expierience... pull up around back to discount tires or whoever and ask for sticky lead fir your rc my guys laughed asked to see it ( drive it) and then handed me 50 oz worth of strips, I asked for 10... needless to say I went and got some new kicks for my Tahoe from them...

|

| |  |

| | #20 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

Oreillies auto parts wanted 50 bucks for a box.... Edit: oh and the sedonas did not work well at all today, seriously worse than the stockers on the environment I was driving in, especially once they were a little wet. Last edited by Crawford; 08-11-2011 at 10:42 PM. | |

| |  |

|

| |