| | #81 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

Im sorry to say.. BUT IT LOOKS WAY OFF.. look at the pics in the thread.. looks like your holes are mounted a few mm closer to the center. V3's Good Guy Fastback | |

| |  |

| Sponsored Links | |

| | #82 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

In his pic the hole is 3/4 from edge of the plate, mine is 7/8ths so thats explaining the 1/8th inch gap I have between the motor mounting surface to the frame. | |

| |  |

| | #83 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

Ah well, at least we know whats wrong.. I think if Juan can get the message by tomorrow, and sends it by tomorrow, you could possibly be able to get the plate before saturday. fingers crossed. | |

| |  |

| | #84 | ||

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

Quote:

and I still have the off-set issue. Juan is the final word hopefully he'll be back in action tomorrow. and I still have the off-set issue. Juan is the final word hopefully he'll be back in action tomorrow.

| ||

| |  |

| | #85 |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

|

ooh, should have read instead of looking at just pics. my bad. Lol! this it self is getting complicated. but it seems like your tranny could go up forward 1/8" |

| |  |

| | #86 | ||

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

Quote:

| ||

| |  |

| | #87 |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

|

oh snap.. busted! LOL

|

| |  |

| | #88 |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

|

After searching.. Seems like the skid wasnt drilled for the stock endbell too, since the "modified" motors are clearing just fine without a complaint. Sportsman Fastback II fitting ax10 tranny in FASTBACK chassis Last edited by MRCCRAWLER1.9; 08-09-2011 at 01:39 AM. |

| |  |

| | #89 |

| No idea what I'm doing Join Date: Oct 2008 Location: Underground, CO

Posts: 4,529

|

The pictures of DickyT's skid are a forward mounting location. This is something I did with my own personal skid, Richard liked it and asked for the same thing. The forward mounting of the motor requires grinding down the motor mounting plate to clear the chassis in the front...something Richard and I both didn't mind doing. This actually started way back before the Fastback with the FF-4 (FF-4s and Fastbacks share the same geometry)  Only a few people have asked for this to be done, and most people prefer the standard mounting location. The standard location is more driveshaft friendly, and gives more room overall. Richard is just one of those rogue kind of crawlers. Your problem looks to be the way the can extends out the back on the stock motor. The photos of jlsandkes truck shows the same skid you have...I drill them all together in batches. A few solutions: 1. New motor with a more exposed endbell like the pictures in jlsandkes thread. I don't know much about the stock motors, but I only run Holmes motors now and love them. Brood is also a very sought after motor. 2. New skid with a forward mounting location. 3. Drill the skid you have now on the other side. The skid is symmetrical (as you have already discovered by flipping it). I have had people order a blank skid before, screw up the holes when drilling and then just flip it and drill again. Let me know what you decide on. Last edited by C*H*U*D; 08-09-2011 at 09:53 AM. |

| |  |

| | #90 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

I didn't realize the stock motor was so long. Now which hh motor to go with... Hmm.... Thanks mrc and juan! | |

| |  |

| | #91 | |

| I wanna be Dave Join Date: May 2011 Location: Lost in Oregon

Posts: 4,450

| Quote:

wow...this was like three pages ago or something...lot's of chat since I visited last. I'm running 55t Integy's...I must admit, I take care of them though...clean the com, check the brushes and keep the ends well lubed. that's from the old days I guess back when all you had was a brushed motor. I haven't seen any issues with them so far...and for the price, well I guess I can't complain even if one or both failed. MRC seems to like the wheel speed a lot...seems like a 35t might be a bit much for your rig Crawford....just my 2 cents... | |

| |  |

| | #92 | |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| Quote:

| |

| |  |

| | #93 |

| I wanna be Dave Join Date: May 2011 Location: Lost in Oregon

Posts: 4,450

|

higher wind = more torque...and less wheel speed...I suppose it's a matter of prefferance...I see plenty of wheel speed out of my 55's though. Nothing like Ink's an Meatwad's rigs...but I didn't build this for speed either. When I build the tuber/scaler..that might be quick though |

| |  |

| | #94 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

|

Finished my shock cap mod.... Looks like ass, don't care. It works and wont leak. My sweet vice:  Pilot hole... Apparently the internal recess that looks like a centering mark/punch is actually not aligned with the outside eyelet.... Found out the hard way on 3 other caps.   My super duper drill press...  Special Sauce  Just take a Q-tip and while going around the edge, rotate the tip to get the excess out, helps to poke the UB down with something small like a tooth pick.  Shortened Revo ends  All done up & curing. What also helps seal everything is dabbing the UB onto the rear bladder/seal and then put that in the top of the shock and screw the cap on to seat it till it cures.  |

| |  |

| | #95 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

|

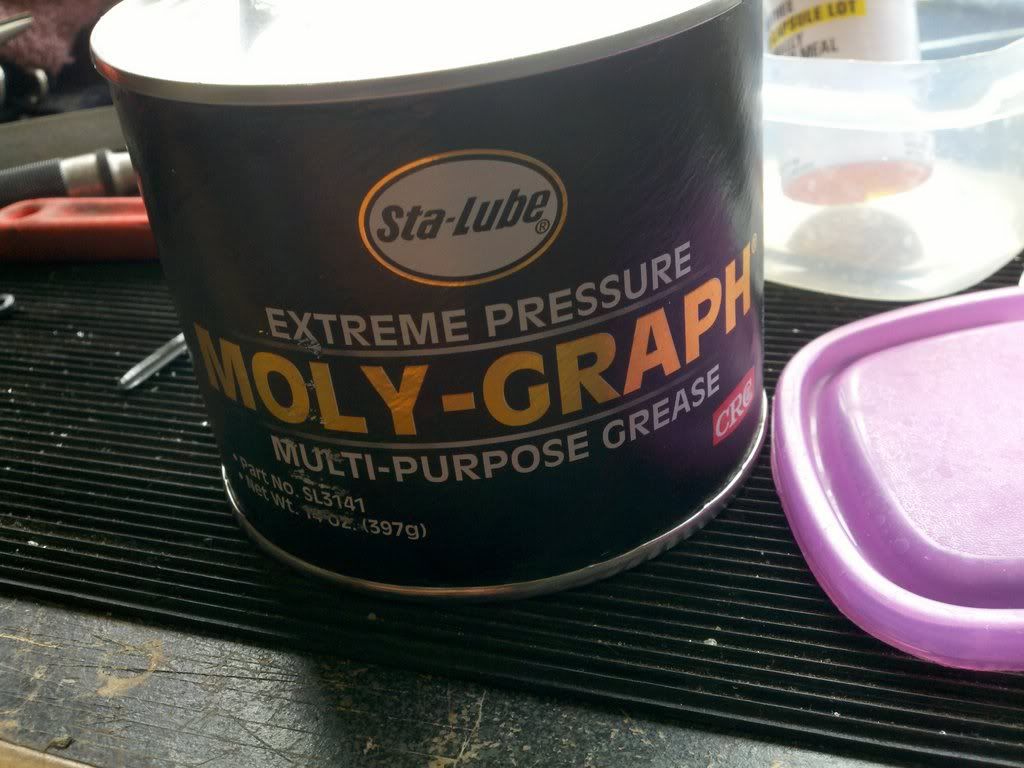

Oh, Picked up some MP grease today, don't believe in spending 15 bucks an oz. on some mystery blend with no specifications or MSDS sheets to back up the cost.... 14oz. 5.99... can't beat that.  packed a pill bottle full of this crap to throw in the kit i'm making. |

| |  |

| | #96 |

| I wanna be Dave Join Date: May 2011 Location: Lost in Oregon

Posts: 4,450

|

Ya...the gear science stuff seemed a bit overplayed...I use marine grease...every time I've pulled the tranny apart the stuff is still stuck to the gears. 14 Oz is going to last a long time...I think it was $6.99

|

| |  |

| | #97 |

| I wanna be Dave Join Date: May 2011 Location: Lost in Oregon

Posts: 4,450

|

So I noticed different #'s on your rod ends...that's not an issue is it? I've never seen that done Crawford....pretty interesting...the gasket stuff keeps it pretty sealed ?? I have an issue with my tops and this would cure it...but I 'm chicken to try it. My tools are limited |

| |  |

| | #98 |

| Quarry Creeper Join Date: Jul 2011 Location: Monterey, CA

Posts: 205

| That stuffs great to but nobody had it. I wish someone carried Schaeffer's 274 grease.

|

| |  |

| | #99 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

| |

| |  |

| | #100 | |

| RCC Addict Join Date: May 2010 Location: Los Altos, California

Posts: 1,509

| Quote:

but then... having too much speed will have its downsides while trying to get technical on the course. personally, i believe 45T is best of both worlds. not too fast, not too little torque. Just about right.. but since you've been running a 27T.... AND stock motor.. seems like a modified 35T will fit you better, because the jump from 27t to 45T is huge... | |

| |  |

|

| |