| | #961 |

| RcBros Hobbies  Join Date: Nov 2005 Location: Oregon

Posts: 4,646

|

I'm not saying it's the right way, but the 7075 winch spools use to be drilled to nearly the diameter of the servo splines. Then the took the titanium gear spline and hammered it into hole which actually did a decent job of cutting them splines. It worked to pull 10-12lb scalers. I have cad files of the Futaba splines, not the others though Sent from my iPhone using Tapatalk |

| |  |

| Sponsored Links | |

| | #962 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

About 55,000 rpm too low. Motion control isn't even in the same galaxy as a machine capable of features that small.

|

| |  |

| | #963 | |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

| Quote:

J | |

| |  |

| | #964 |

| I wanna be Dave Join Date: May 2007 Location: Fairfield ME

Posts: 3,886

| A quick search shows guys using hobby mills to machine aluminum molds for commemorative coins with 1/32 endmills. That seems like comparable work, no?

|

| |  |

| | #965 | |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

| Quote:

And I checked a piece of shittyshittyone with a center punch. Looks like the Hitec and Hudy are that as well from this imprecise test. If this is the case then the robitronic arms are made of hummingbird feces. J | |

| |  |

| | #966 |

| RCC Addict Join Date: May 2012 Location: Folsom

Posts: 1,867

|

What's funny is ive had great luck with robitronic arms. But this comes from a guy who just judges national champs not drives with them |

| |  |

| | #967 | |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

| Quote:

My servo horn is just in a nasty spot for one to be, and my front end is very heavy. Someone should have a field day with that one... J | |

| |  |

| | #968 |

| I wanna be Dave Join Date: May 2007 Location: Fairfield ME

Posts: 3,886

| Maybe I'm just lucky but I never have an issue with any of my racers edge clamping horns. I even gave a buddy my horn mounting bolt since he lost his while we were out and I actually ran it another whole trail run next time we went out before I remembered that it was still missing. Thats on my 4 pole 4s 28mph wraith.

|

| |  |

| | #969 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

So, it is possible... FlyingGiants - View Single Post - Servo spline geometry help I think machining a cutting tool (broach) would be easier than trying to machine the ID profile. I have a few sizes of O1 tool steel. Might be fun to try and cut it on the 4th axis. |

| |  |

| | #970 | |

| RCC Addict Join Date: Mar 2009 Location: The REAL Nor-Cal

Posts: 1,049

| Quote:

Robitronics staying tight, but I have bent them like Joel mentioned above. I have a few of the machined Axial units that seem to be performing well too! | |

| |  |

| | #971 | |

| I wanna be Dave Join Date: May 2007 Location: Fairfield ME

Posts: 3,886

| Quote:

| |

| |  |

| | #972 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

When I was questioning the ability of hobby grade machines, techniques, knowledge and skills? It sounds like quite a challenge regardless.

|

| |  |

| | #973 |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

|

Quite a challenge indeed. I'll see if I can place some bribes and pull some strings before I bite into this on my own. Cool stuff though. J |

| |  |

| | #974 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

I've put out a feeler to one of our machinists that make servo arms for companies like Align, it's no problem. Have a profile of the arm shape we could throw at them? Threaded m3 holes on what lengths from center? I'll bring in higher grade arms if you can help design it. Tool steel, 7075 T6, or grade 5 Ti would be my first choices.

|

| |  |

| | #975 | |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

| Quote:

I just need 1" pin to screw. Additional holes and clamps I do not prefer. Ti would rock. I have some nutty hard 7075 too. The low profile of the Hudy unit is nice. I might just send you the one I have on my rig before I destroy it. It is small but when made of the above materials it would be plenty strong with few tweaks. I'll call you this weekend during an airport sit. I'll be in Utah with Erik hitting new lines and sharing good times. I just need 1" pin to screw. Additional holes and clamps I do not prefer. Ti would rock. I have some nutty hard 7075 too. The low profile of the Hudy unit is nice. I might just send you the one I have on my rig before I destroy it. It is small but when made of the above materials it would be plenty strong with few tweaks. I'll call you this weekend during an airport sit. I'll be in Utah with Erik hitting new lines and sharing good times.J | |

| |  |

| | #976 |

| RCC Addict Join Date: Oct 2006 Location: crawlifornia

Posts: 1,612

|

I know this is not as fun as making a new more durable servo arm, but what about just making a sturdy slam guard to protect the whole area? Please excuse the crude paint interpretation of my idea, I just took a few minutes and I suck at it, but I think you get the idea. The grey is a flat plate, perhaps 7075, perhaps thick Delrin, or I prefer UHMW (either one to keep it from hanging up) Basically the yellow dots are your tie in points, the center one would tie into the upper link mount, the two on the right side would use spacers to reach the rear driver side servo mount screw, and the link mount area, giving you 3 solid mounting points that will not bend, and thus will protect your whole frontal area in a rock slam. My logic behind this approach is that if you are going to slam a rock that hard that you might bend an arm, imagine what the transfer of energy is to the servo, and related gears, case etc. By making a more rigid - non bendable arm, you might be sending more force to the servo. Calculate the leverage at the end of the arm as it slams, which will be twisting or tweaking the out put gear. You may just crack the servo case, or worse. No big deal if you're just out practicing, but if that happened in a comp, well.. ya know.   |

| |  |

| | #977 |

| Quarry Creeper Join Date: Jul 2009 Location: Woodburn, Oregon

Posts: 358

| Quote: |

| |  |

| | #978 |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

|

Hey Rockhugger, Thanks for the suggestion and pedicure. I think I'll skip the plate as a tougher horn should fix the problem and the mount points don't exist. There is about 0.05" of material on the top of my front link mount for example and I really would rather the the horn take a beating. That mount took 6 hours to make. Thanks again. Cool graphic. J |

| |  |

| | #979 |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

|

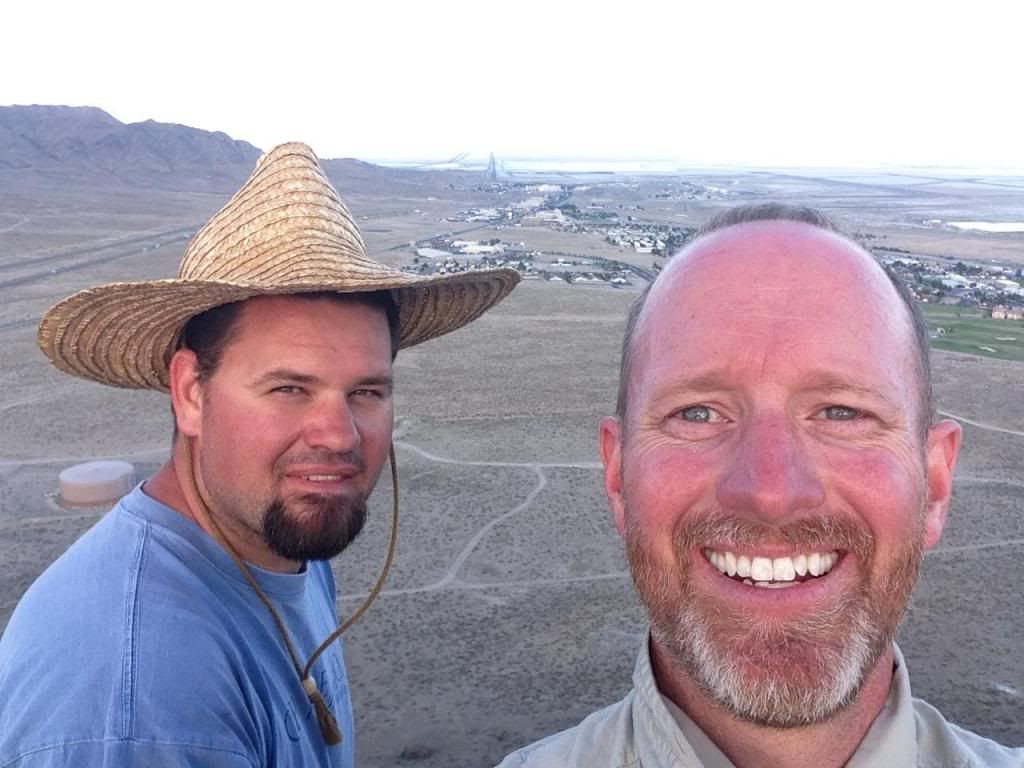

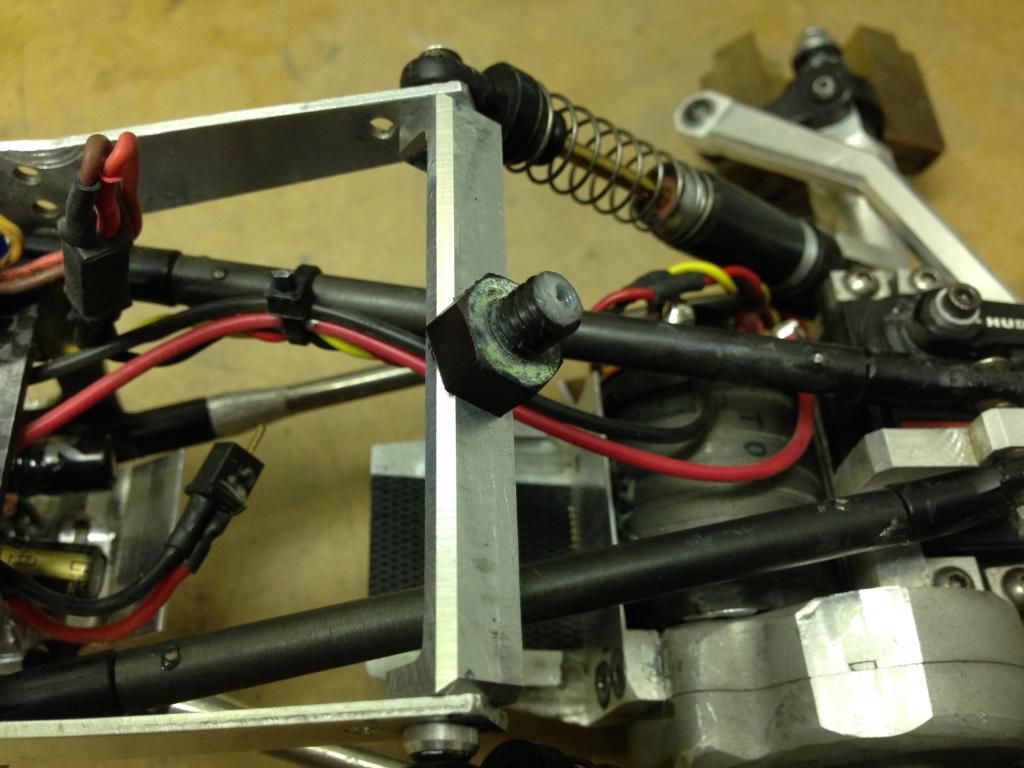

Thanks a ton Erik for taking the weekend away from your family to hang out and crawl. I had a blast. Those were some sick bounty lines and you were spot on regarding bounty climbs and pins. First, some of the awesome views.    And some scary blokes.   Now regarding tires. My pins struggled at black rock. I figured when we got to Wendover they would improve. If it was a comp they would kick ass...not on Erik style bounty lines. Maximum forward bite and tread life were clutch. Luckily we run plate wheels so he gratiously raided his sporty and hooked me up with some Rovers. The improvement was dramatic and I was back in the game. Erik's twin stick skills were hard to match with a 4PK. The instant rear control was critical. He pulled some climbs that I could not make. Man that was fun! I guess I was a "team" driver for the weekend    After struggling with one line for a while I noticed my rig was acting funny. This may have been part of it. Erik raided his sporty yet again and we were on our way.  So I dumped the overly complicated design above to go back to the bomb proof design that preceded it...with a little fat trimmed off.  Thanks again Erik. Looking forward to our next outing...and I'll definitely have some Bounty Shoes optimized by them. J |

| |  |

| | #980 |

| I wanna be Dave Join Date: Dec 2009 Location: .

Posts: 7,967

|

Blue Voodoos.

|

| |  |

|

| |