| | #1041 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

| |

| |  |

| Sponsored Links | |

| | #1042 |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

| |

| |  |

| | #1043 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

I could expand but... Plastic cutting EM's need to be the sharpest of the bunch. Don't use them to cut metals. Judging by your chip size on the 7075 cases the 4FL, while not ideal, is serving you fine. Most speed, feed and EM geometry recommendations are made for CNC machines pushing much harder than you are. Can you engage your lathe carriage to act as a power feed while you are milling? |

| |  |

| | #1044 | ||

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

| Quote:

Quote:

My mindset is always pushing the equipment almost as hard as possible, so that's probably why I've got two flute on the brain 6063, yucky stuff. It's so gummy | ||

| |  |

| | #1045 | ||

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

| Quote:

Quote:

J | ||

| |  |

| | #1046 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

6061 cuts just as horribly, like bubble gum.

|

| |  |

| | #1047 |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

| |

| |  |

| | #1048 |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

|

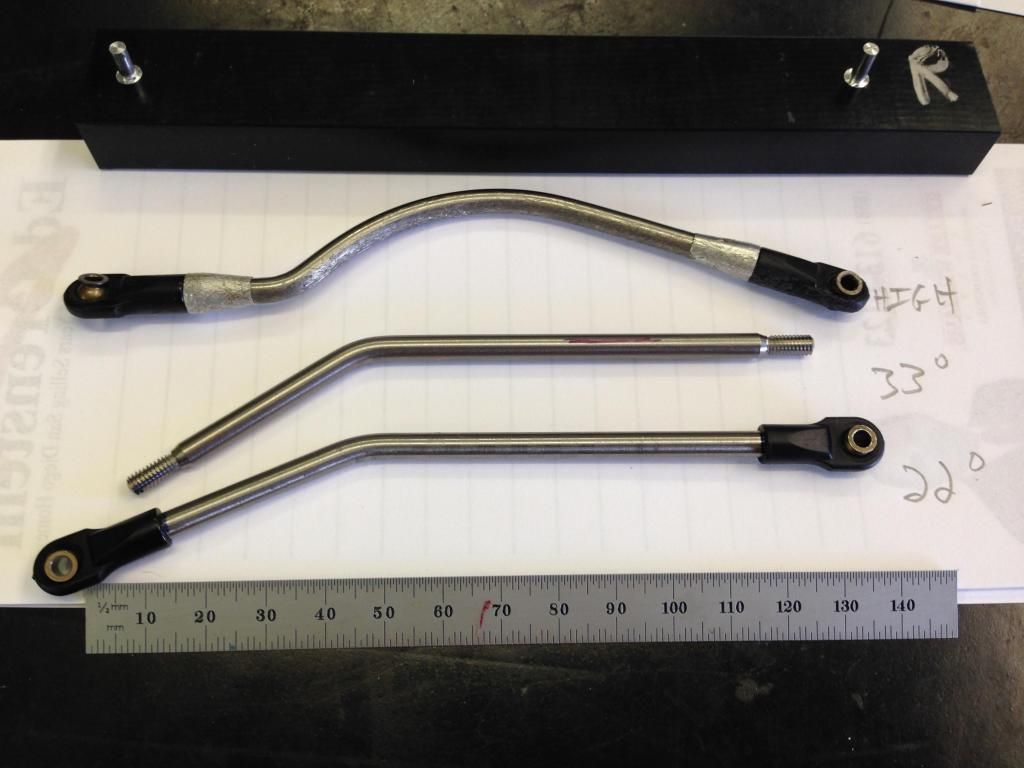

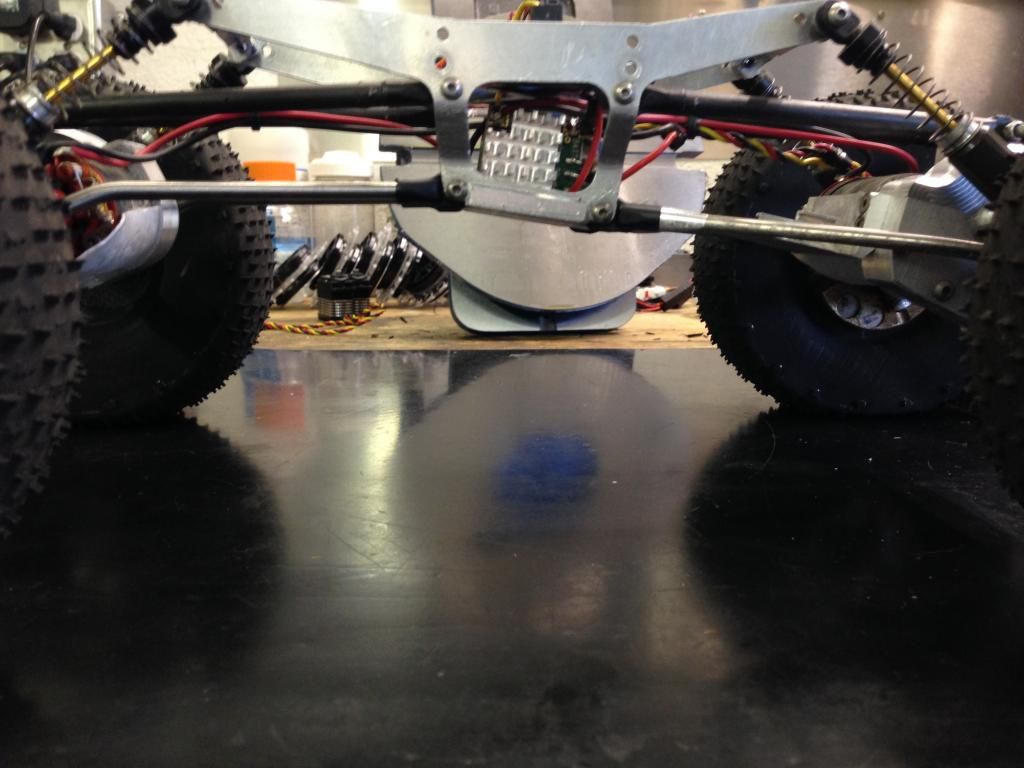

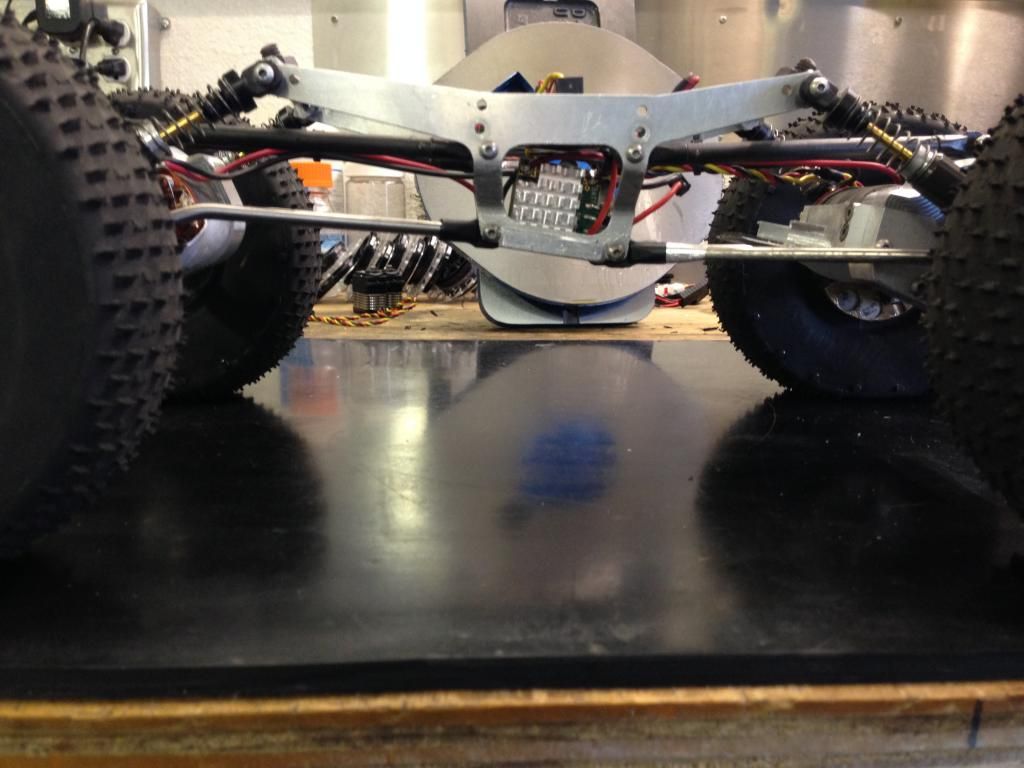

Ok gents, Got some more links made this weekend. Will test in the next couple of nights. In order to make link sets that were bang on length spec I first made a link jig. I'll never make another link without using this. It allows links to be matched with a couple 0.001" of each other at the most. Should have done this a long time ago.  Below see the current and two single bend test versions.  I started with bending some 130mm Vanquish Product Ti links to 33deg. For my setup the 130mm/33deg still had a lot of clearance. I then made some 127mm from G5Ti and bent them to 22deg. These are installed in the pics below. Full droop.  Approx ride height.  I am still nervous that the rear motor is hanging out in the open with this single bend conformation. J |

| |  |

| | #1049 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

Want a little more motor protection? I have some 1/4 sleeve faceplates that I made for giggles. Other than bending a brush hood you wouldn't have much else to worry about.

|

| |  |

| | #1050 |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

|

That's pretty cool...but the hood/brush end is the only end I'm worried about. My cases will keep the other end safe. New machine up and running? J |

| |  |

| | #1051 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

Yep, running strong. Mixing fresh coolant right now before the days work. I'm in the middle of designing a hood cover and endbell assembly at the moment, you interested huh? It will hurt ground clearance about 1/8th inch, that ok?

|

| |  |

| | #1052 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

Yep, running strong. Mixing fresh coolant right now before the days work. I'm in the middle of designing a hood cover and endbell assembly at the moment, you interested huh? It will hurt ground clearance about 1/8th inch, that ok?

|

| |  |

| | #1053 |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

|

I'm thinking a hemi-circular end bell cap 0.040" thick of 7075. I need to flesh it out on paper. 0.125" is a little much for me at first glance. Looking forward to seeing your design.

|

| |  |

| | #1054 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

.040" thickness is fine, but it has to reach over the hoods without touching and that is where the extra size comes into play. I was overguessing to cover my ass |

| |  |

| | #1055 |

| Wanna get? Gotta want.  Join Date: Apr 2010 Location: SLC, UT

Posts: 7,052

|

Other than the brush hood, what is your concern with the motors? I know its way against the normal thinking but I have not run any type of motor protection in about 2yrs(?). I have not noticed any problems or issues other than some scratches that easily buff out on the cans. For the brush hoods, maybe John can hook you up with the reverse spring mod like EddieO does for me? Keeps everything nice and out of the way.  |

| |  |

| | #1056 | |

| 2013 2.2P Nat. Champion  Join Date: Sep 2009 Location: BorderLine Crawlers Season 3 is on!

Posts: 2,584

| Quote:

J J | |

| |  |

| | #1057 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

I do have plenty of old Epic motors here we could scrap the hoods from, might as well do something to make old parts useful. The only hitch is that somebody bought all my reverse springs, and the hoods are all laydown style which is too wide for 5 slot comms. At that point might as well just integrate the guard into a sub hood plate, it would be about the same effort as cobbling things together with parts that are no longer available. |

| |  |

| | #1058 | |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

There was standup hoods made for reverse springs, as well as P-94...the laydowns are easier to find though, as they all came like that... Why not just cut some brushes down for the 5 segment arms... The real problem is getting stiff springs as the trinity purple was the stiffest trinity made in a reverse...Orion made some stiffer ones, but I bought them all long ago Later EddieO Quote:

| |

| |  |

| | #1059 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

I don't want Joel dealing with teeny brushes that are limiting the power, and having to cut brushes every time he needs a refill. I'm trying to keep him running affordably, not tie him to my titty with a weird ass setup with crappy performance just so he can gain a hair. so, you saying you have reverse brush springs? |

| |  |

| | #1060 |

| I wanna be Dave Join Date: Apr 2007 Location: Arlington, Washington

Posts: 2,303

|

I dunno about limiting power with smaller brushes...the Orion V2 brushes were smaller....and handled 7 turns with no issue. They even released a smaller round brush on the Oscar Jansen edition (team motors had been running them for 2 years prior) that won a world championship....a 7 turn makes a lot more power than any crawler motor does.....in fact back in the racing days the Reedy MVP stock motor came with laydowns but we reduced the width as the motor made MORE power that way.......Mike Reedy himself built them like that, as did Big Jim and every other builder. Sure we use more voltage now, but the slot cars guys use 14 volts all day long with little brushes tons of amp draw and power out of those little motors spinning 250k rpm... And of course I have reversed springs. I have tons of purples, reds, greens from trinity, along with a ton of the 175, 150 and 135 Orion versions. Orion cleared it all out long ago after the v2 came out....I bought it all for next to nothing. Later EddieO |

| |  |

|

| |