| | #181 | |||

| RCC Addict  Join Date: Aug 2005 Location: New Oxford PA

Posts: 1,290

| Quote:

Quote:

Quote:

| |||

| |  |

| Sponsored Links | |

| | #182 |

| RCC Addict  Join Date: Aug 2005 Location: New Oxford PA

Posts: 1,290

|

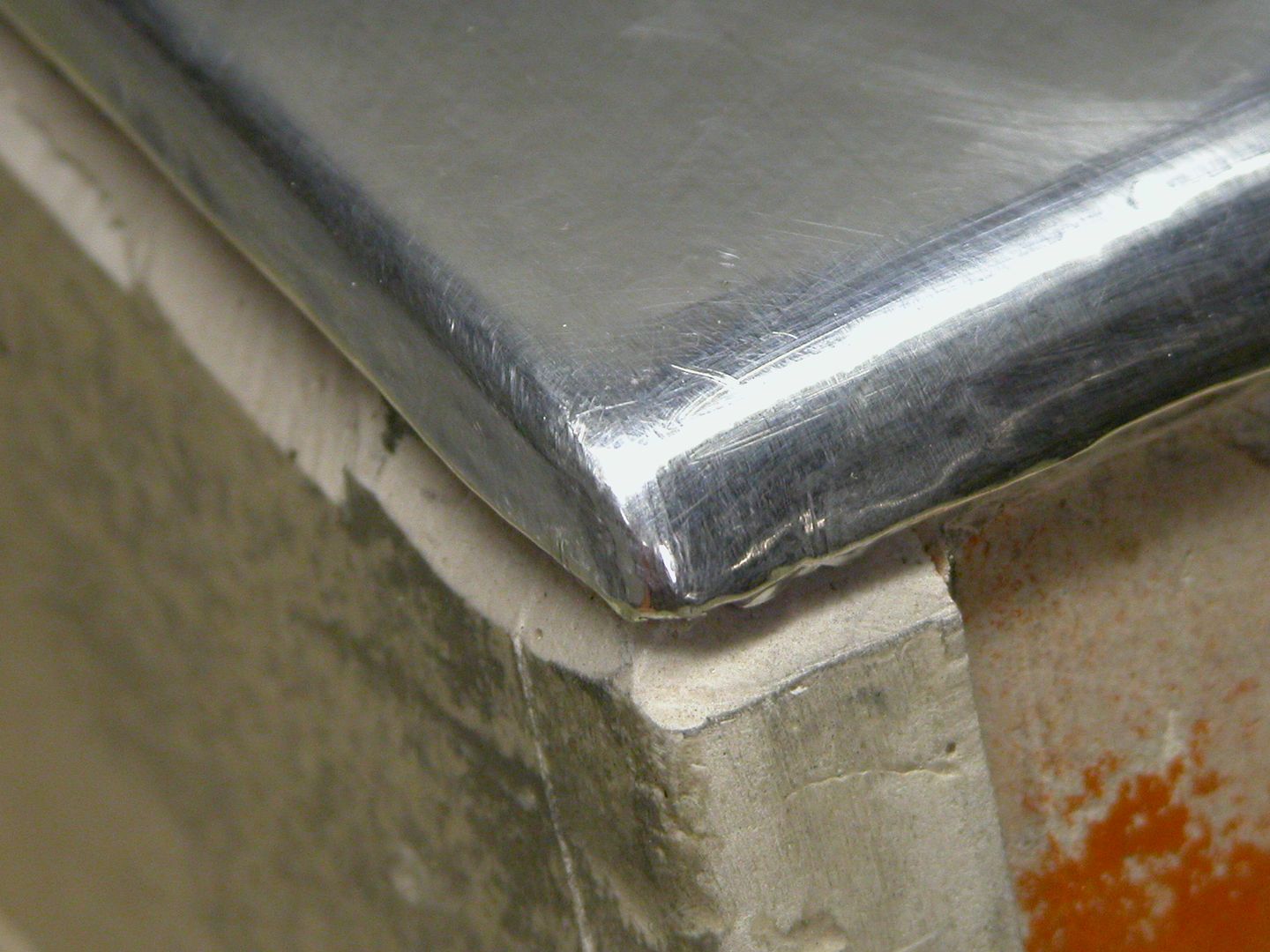

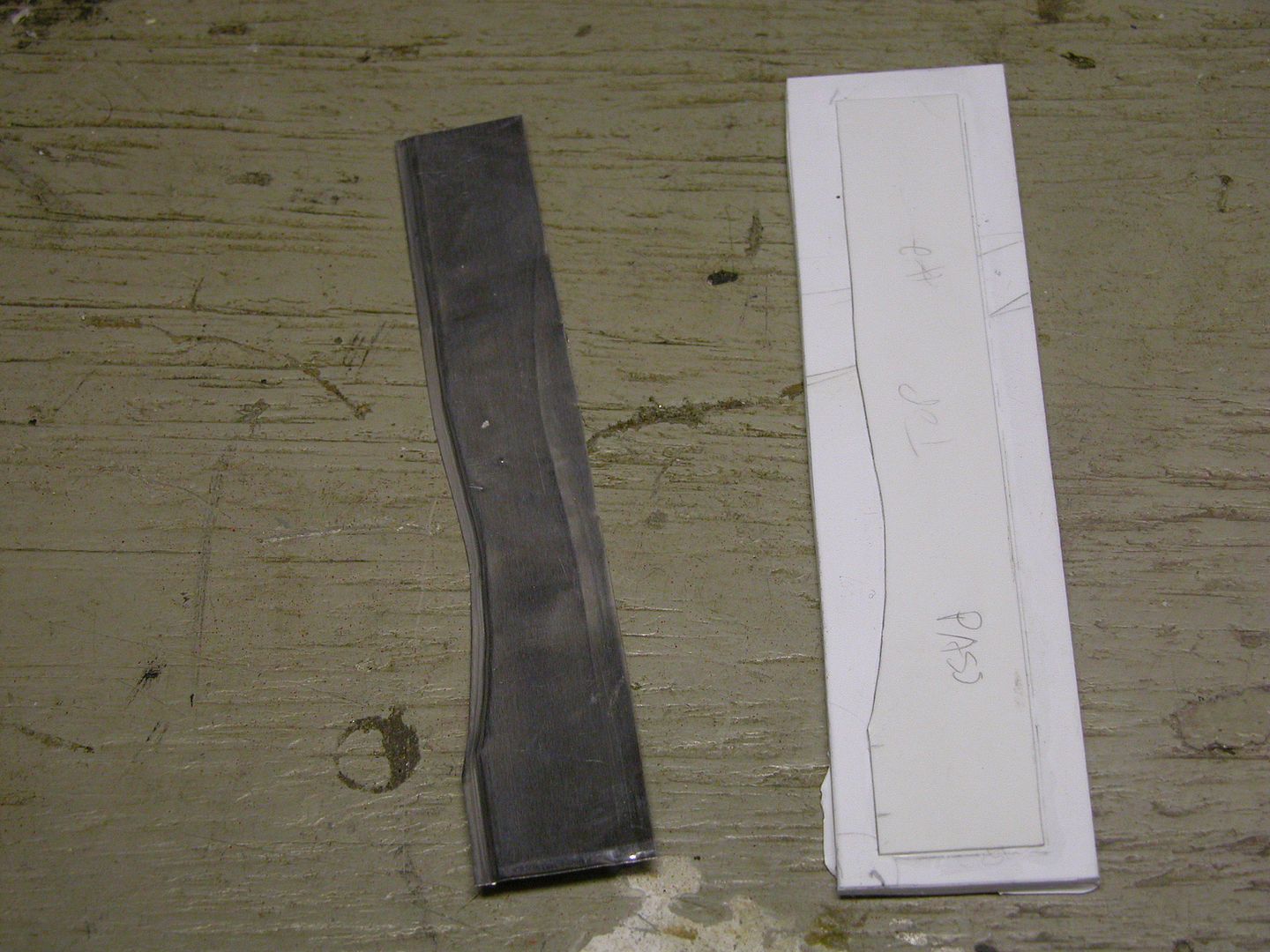

A bit more done, I took the mold i had made a while ago for the roof and modified it a bit to reflect the real thing. First i cut the molding off to have the lip where the glass will lay  I am also getting better at forming the metal. i was able to do it this time without any folds.  Then in the back i cut a recess to allow me to fold the metal around the body line. this will get attached to the top of the B pillars.  After i made the new roof i did a quick mock up. Everything seems to fit pretty good so far    I still have a long way to go but at least it's starting to look like something. |

| |  |

| | #183 |

| Quarry Creeper Join Date: Aug 2008 Location: Columbia, SC

Posts: 395

|

That is unreal |

| |  |

| | #184 |

| Quarry Creeper Join Date: May 2008 Location: Lafayette, Indiana

Posts: 277

|

its gonna be sad to see it get destroyed |

| |  |

| | #185 |

| RCC Addict Join Date: Feb 2008 Location: tauranga north island new zealand

Posts: 1,786

|

Polish and it can be a shelf queen  . .God dam amazing work,scratch building taken to another level,4sure. |

| |  |

| | #186 |

| Rock Stacker Join Date: May 2008 Location: Switzerland

Posts: 65

|

this is really awesome! i really admire you guys molding metal bodies. this is really first class scale business!!!

|

| |  |

| | #187 | |

| RCC Addict  Join Date: Aug 2005 Location: New Oxford PA

Posts: 1,290

| Don't feel bad, The best part it i can make more!  Quote:

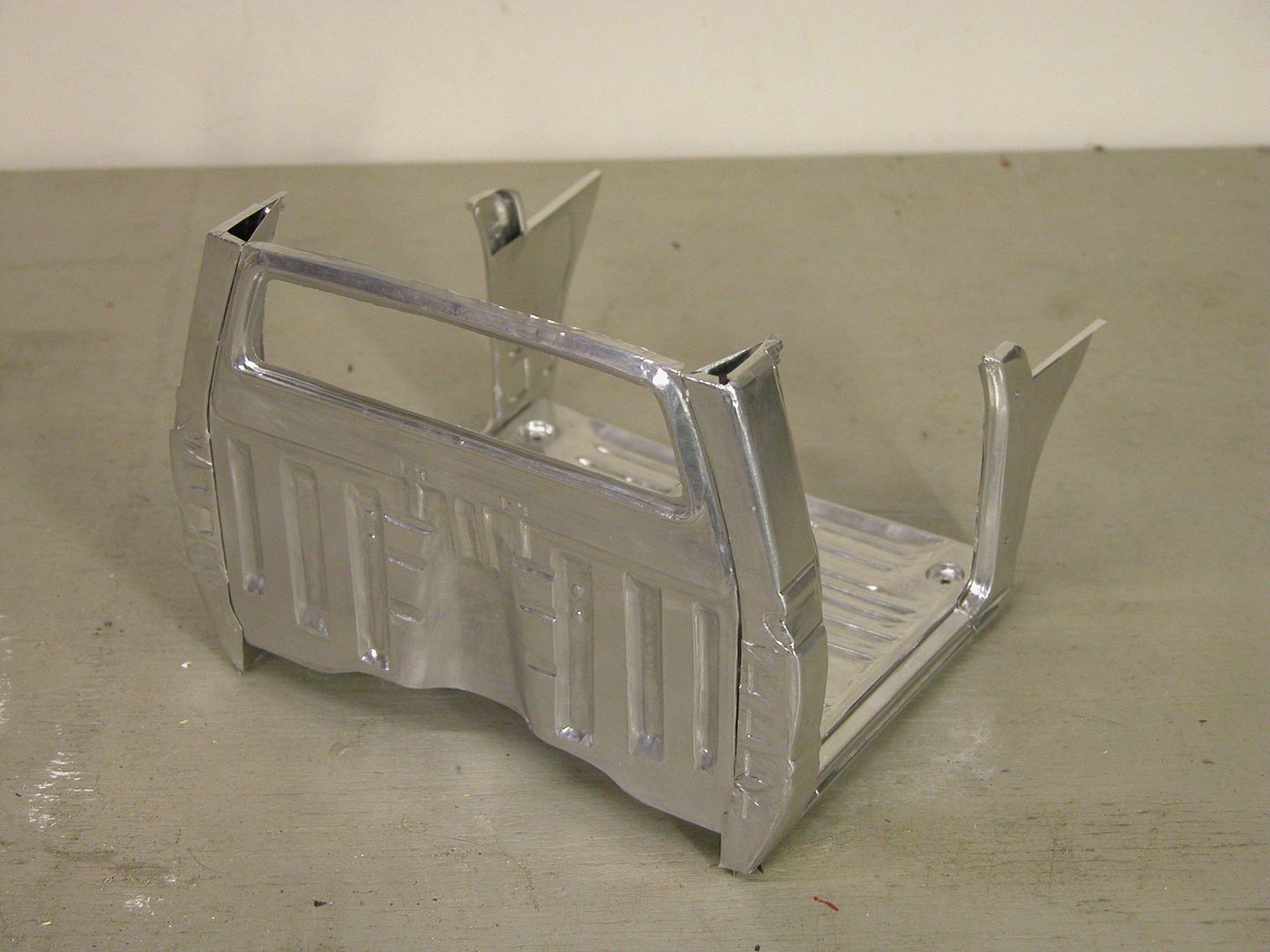

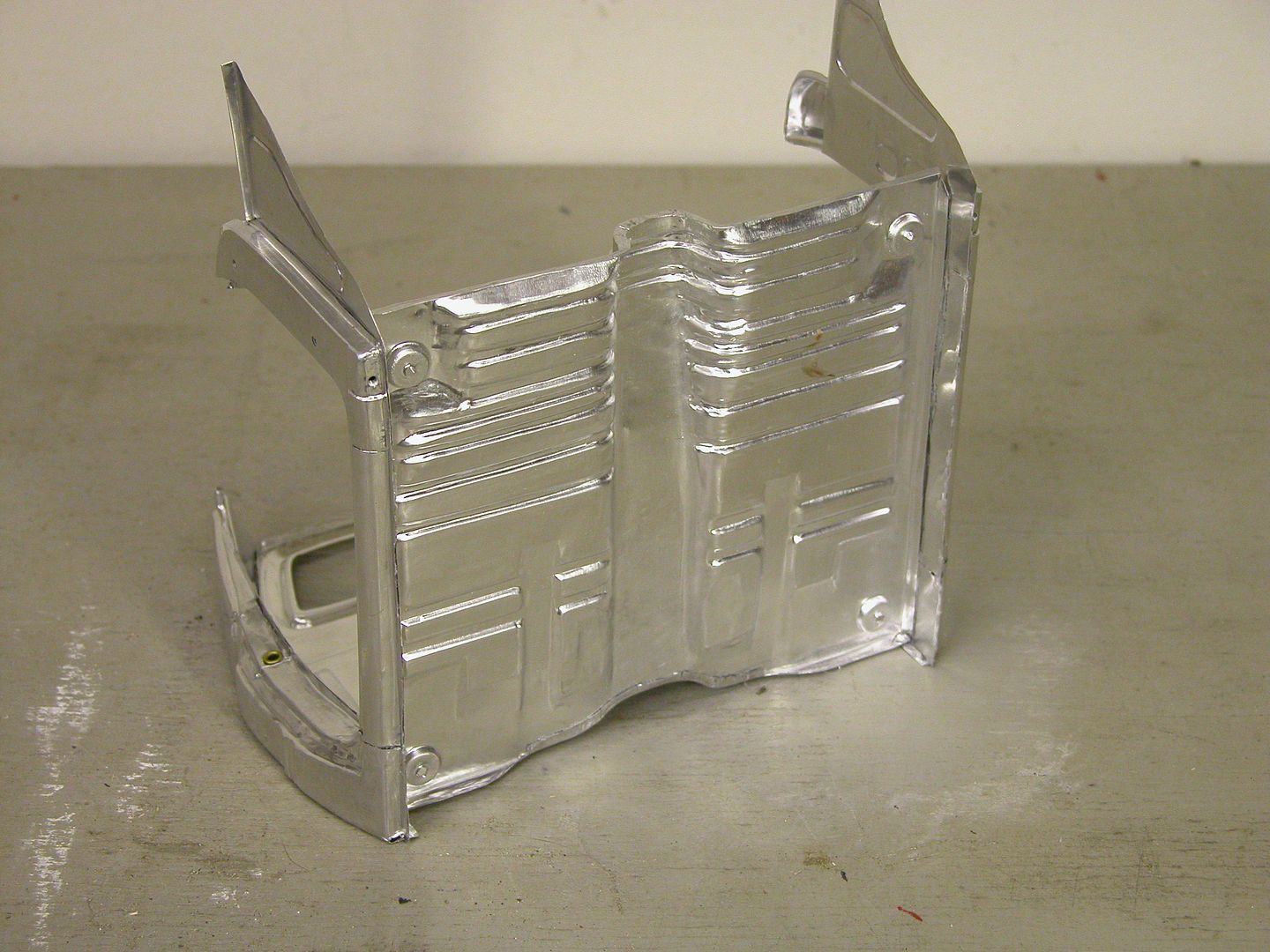

I got my rear axle almost done (need to thread the axle yet) but enough to do some more mocking. I wanted to get a feel for it before i started the firewall. I'm stressing out about it because it is critical i get it right or nothing will fit. Here is some eye candy for now.       More to come! | |

| |  |

| | #188 |

| Quarry Creeper Join Date: Dec 2009 Location: Brentwood

Posts: 341

|

amazing work! cant wait to see it done.. what kind of metal are you using? like the thickness and where did you get it? thanks!

|

| |  |

| | #189 |

| Rock Crawler  Join Date: Feb 2007 Location: Peoria, Arizona

Posts: 919

|

Awesome work as always. so forgive me for this next question if you have answered it before, but why not do this in brass or tin or steel so you could braze or solder the body parts together? Are these metals too hard to form to the molds? thanks! I am to ADD to read the whole thread! |

| |  |

| | #190 |

| Pebble Pounder  Join Date: May 2008 Location: El Monte

Posts: 177

|

what..... im soo jealous right now. |

| |  |

| | #191 | ||

| RCC Addict  Join Date: Aug 2005 Location: New Oxford PA

Posts: 1,290

| Quote:

Quote:

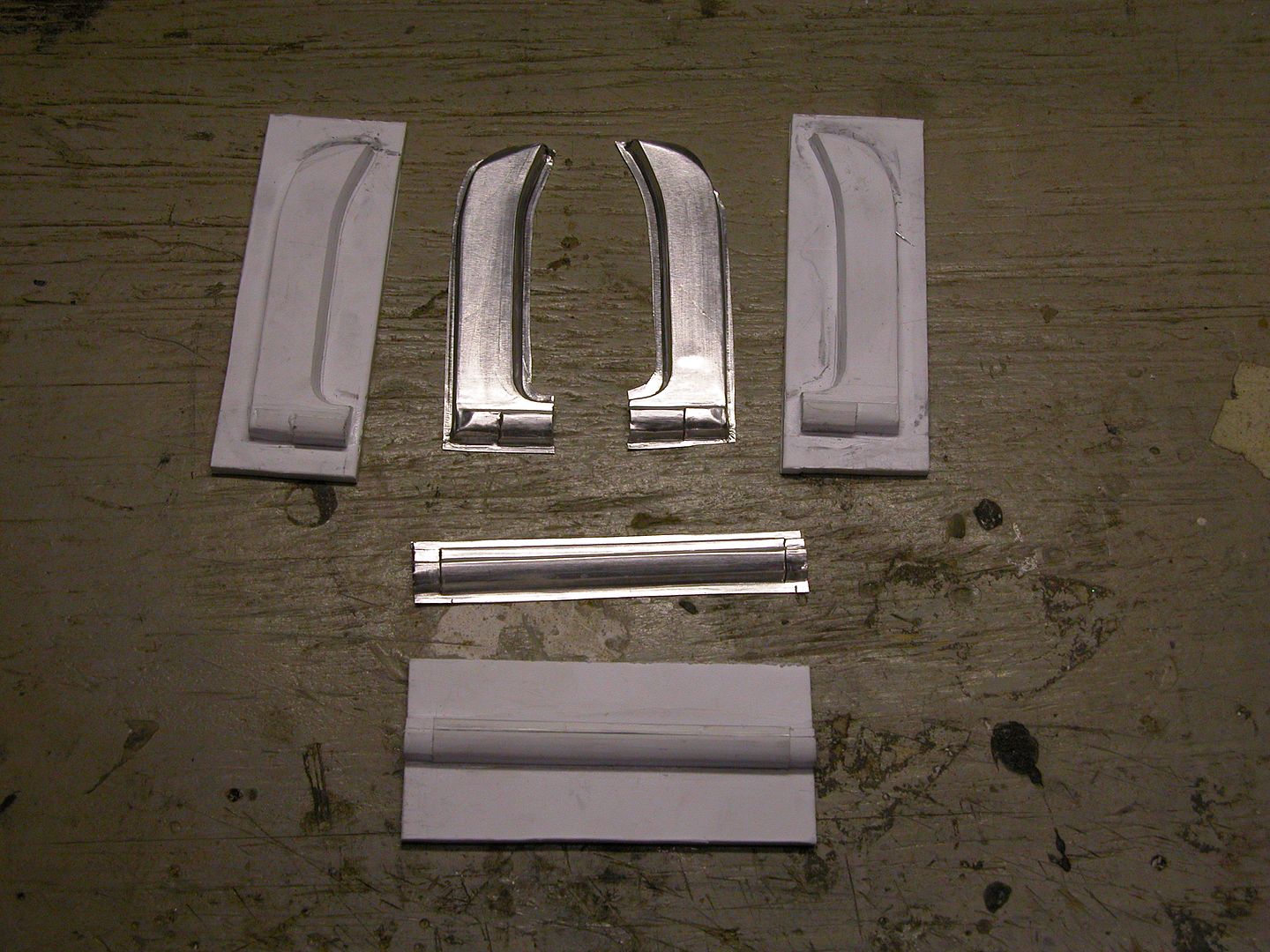

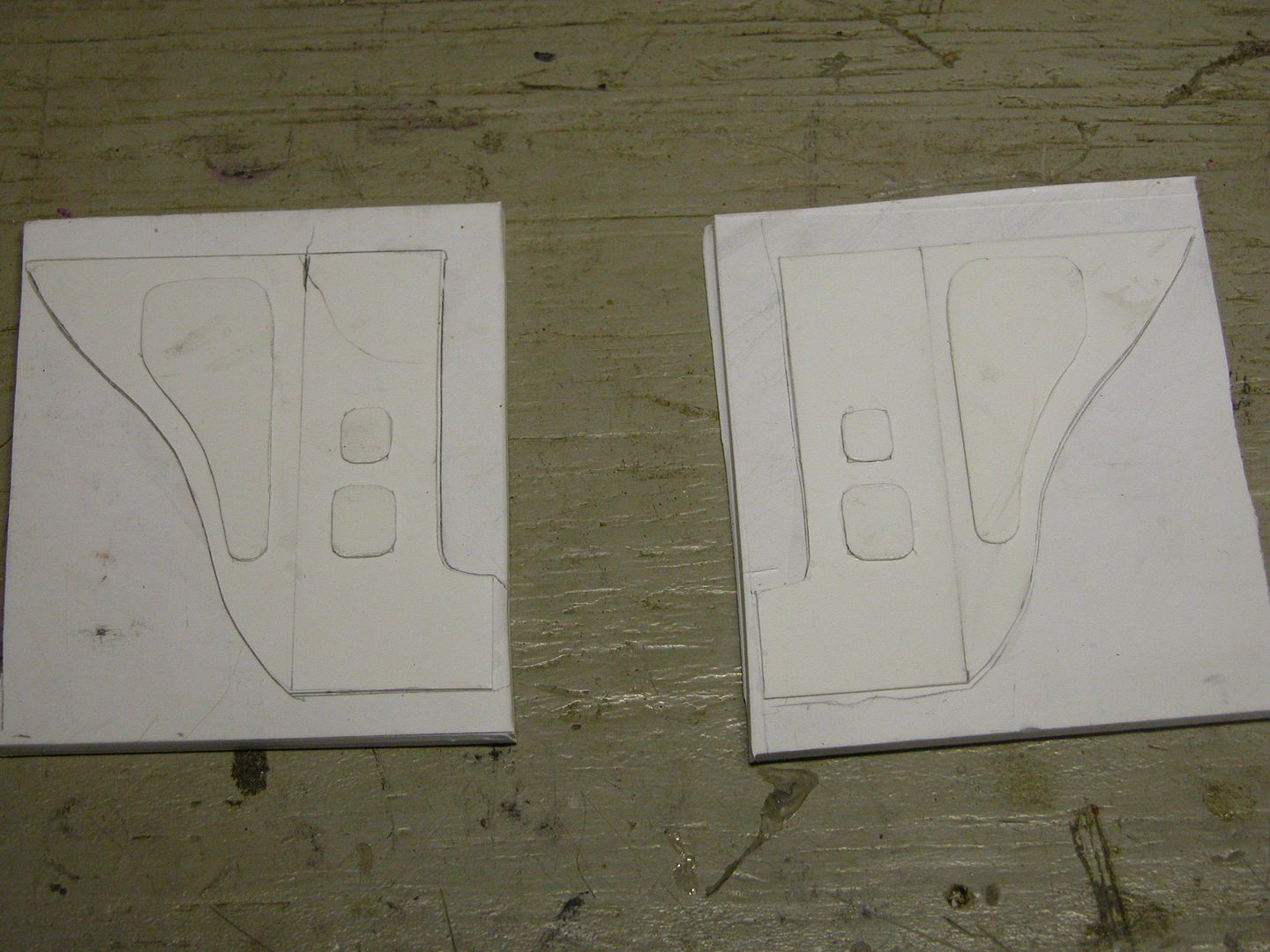

Also I have yet to find steel or tin this thin, if i ever do i will be definatly using that as i can truly replicate rust! More progress, I made 3 more molds. These are the outer rockers and the lower A pillar support.  And i finally started assembly of the cab.  I'm starting to get excited! | ||

| |  |

| | #192 |

| RCC Addict Join Date: Dec 2007 Location: Calgary

Posts: 1,575

|

you sir are a master of metal forming. Well done  |

| |  |

| | #193 |

| Pebble Pounder Join Date: Apr 2009 Location: Crawlerado Springs

Posts: 126

|

Holy chit did!

|

| |  |

| | #194 |

| Rock Crawler  Join Date: Jul 2005 Location: MD

Posts: 810

|

Your getting pretty close, If you are finished for Motorama somebody from a magazine/TV better be there to see this!

|

| |  |

| | #195 |

| Newbie Join Date: Jan 2010 Location: St. George

Posts: 6

|

Looks great!!! Subscribed!

|

| |  |

| | #196 | |

| RCC Addict Join Date: May 2008 Location: Southern,WV

Posts: 1,136

| Quote:

| |

| |  |

| | #197 |

| Rock Crawler  Join Date: Sep 2006 Location: Lititz

Posts: 787

|

Master Blake, your Yota is going to be the sickest truck to ever hit the trails! Everyone at Motorama is going to have a treat. Last edited by chevellian; 01-17-2010 at 01:36 PM. |

| |  |

| | #198 |

| Pebble Pounder Join Date: Dec 2004 Location: DFW

Posts: 133

|

WOW !!!! Awesome build. One more thing to say "ARTIST"  Can't wait to see this thing done. |

| |  |

| | #199 | |||

| RCC Addict  Join Date: Aug 2005 Location: New Oxford PA

Posts: 1,290

| Quote:

Quote:

I never thought about the shim stock before, the size isn't to bad and the price is reasonable. I might get some test pieces and see how well they work. they just might be the ticket  Quote:

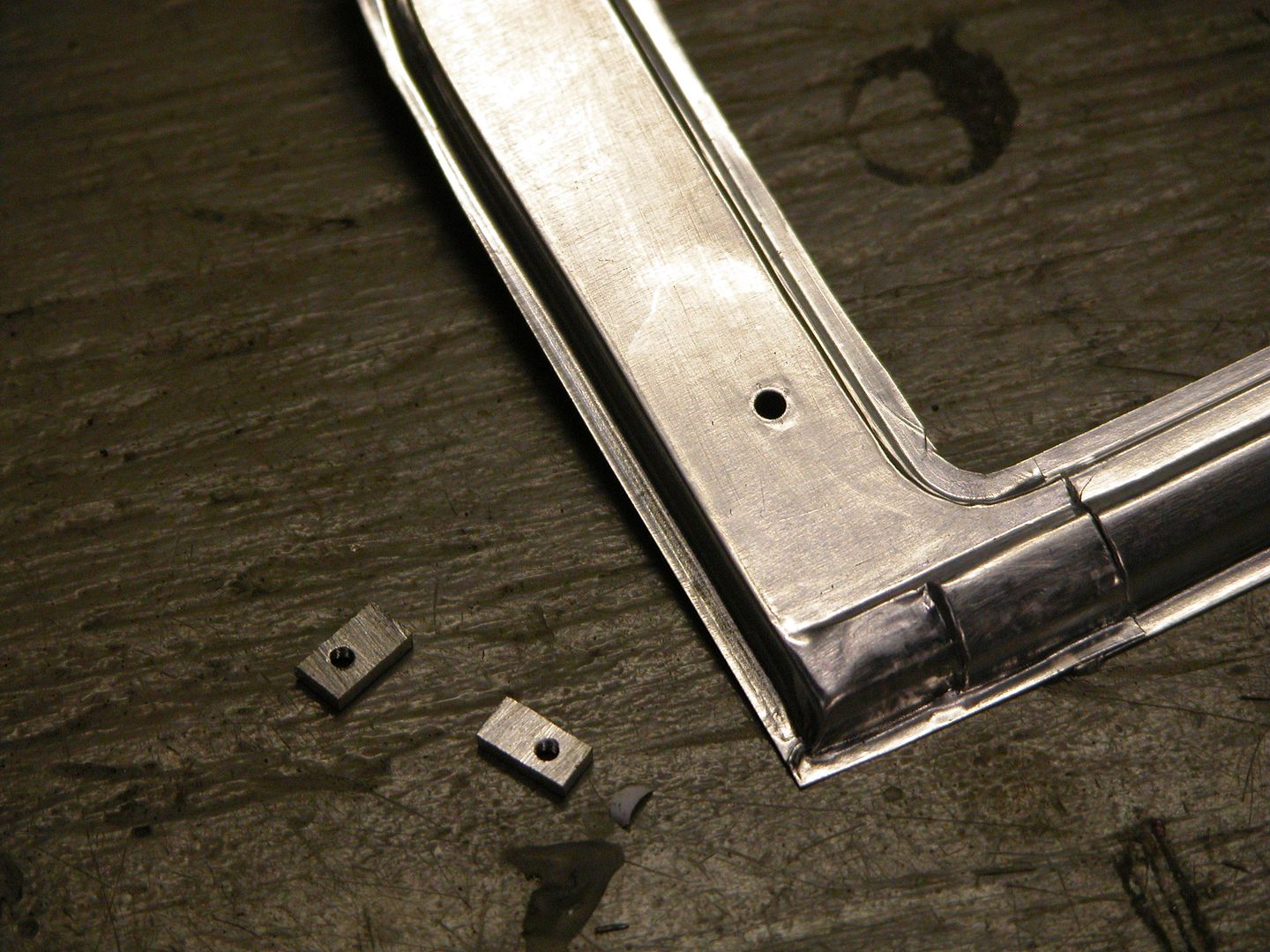

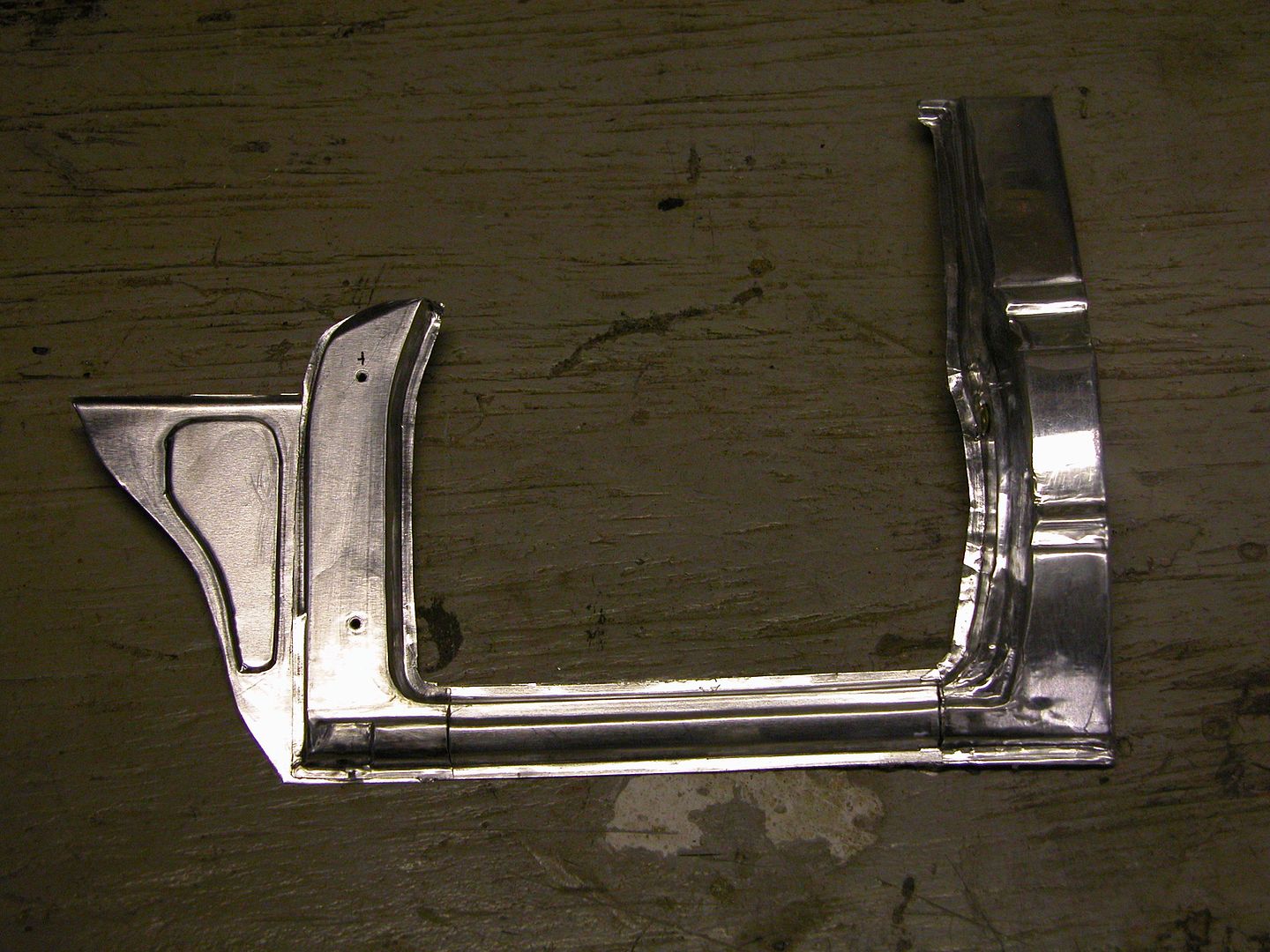

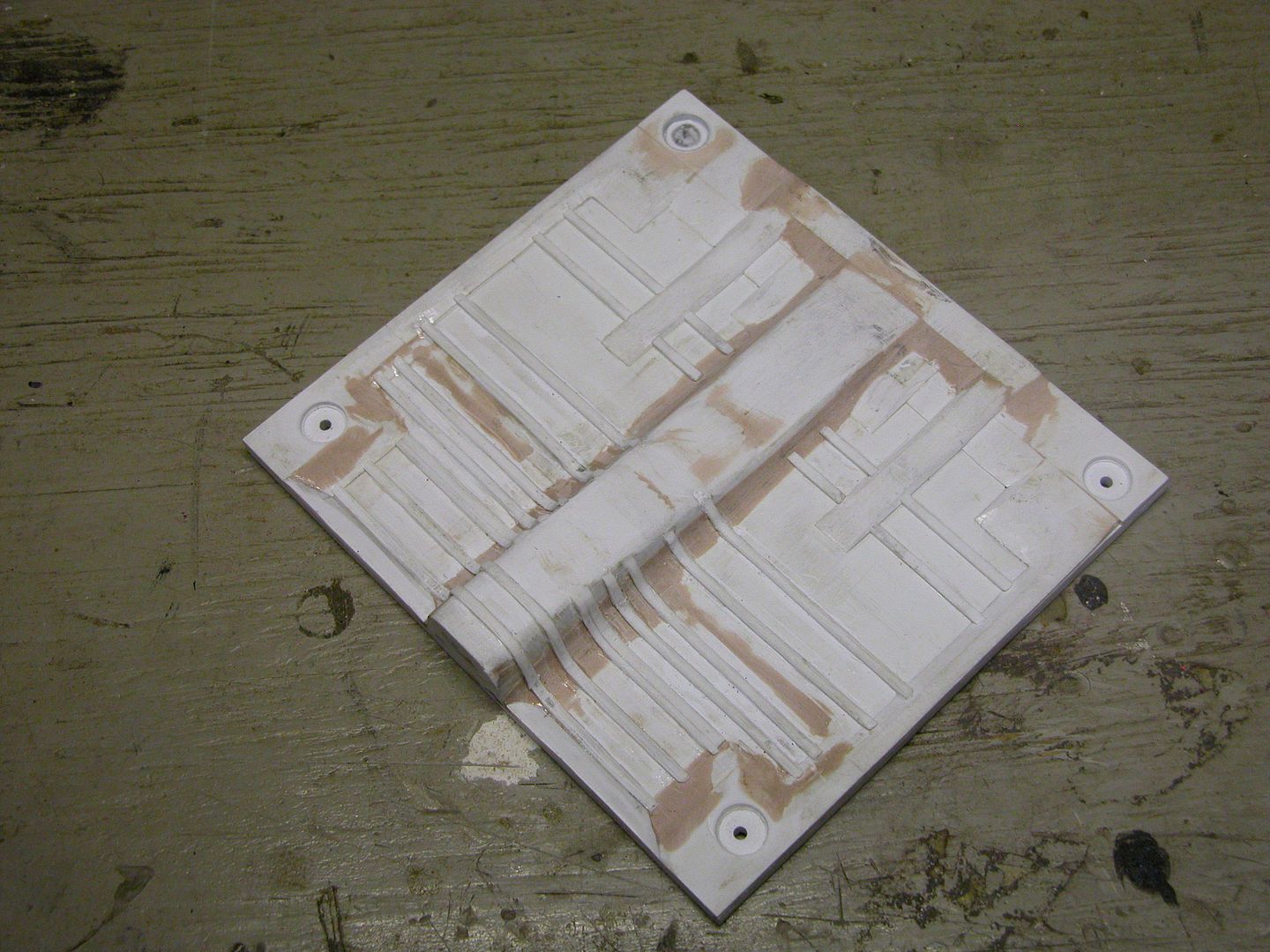

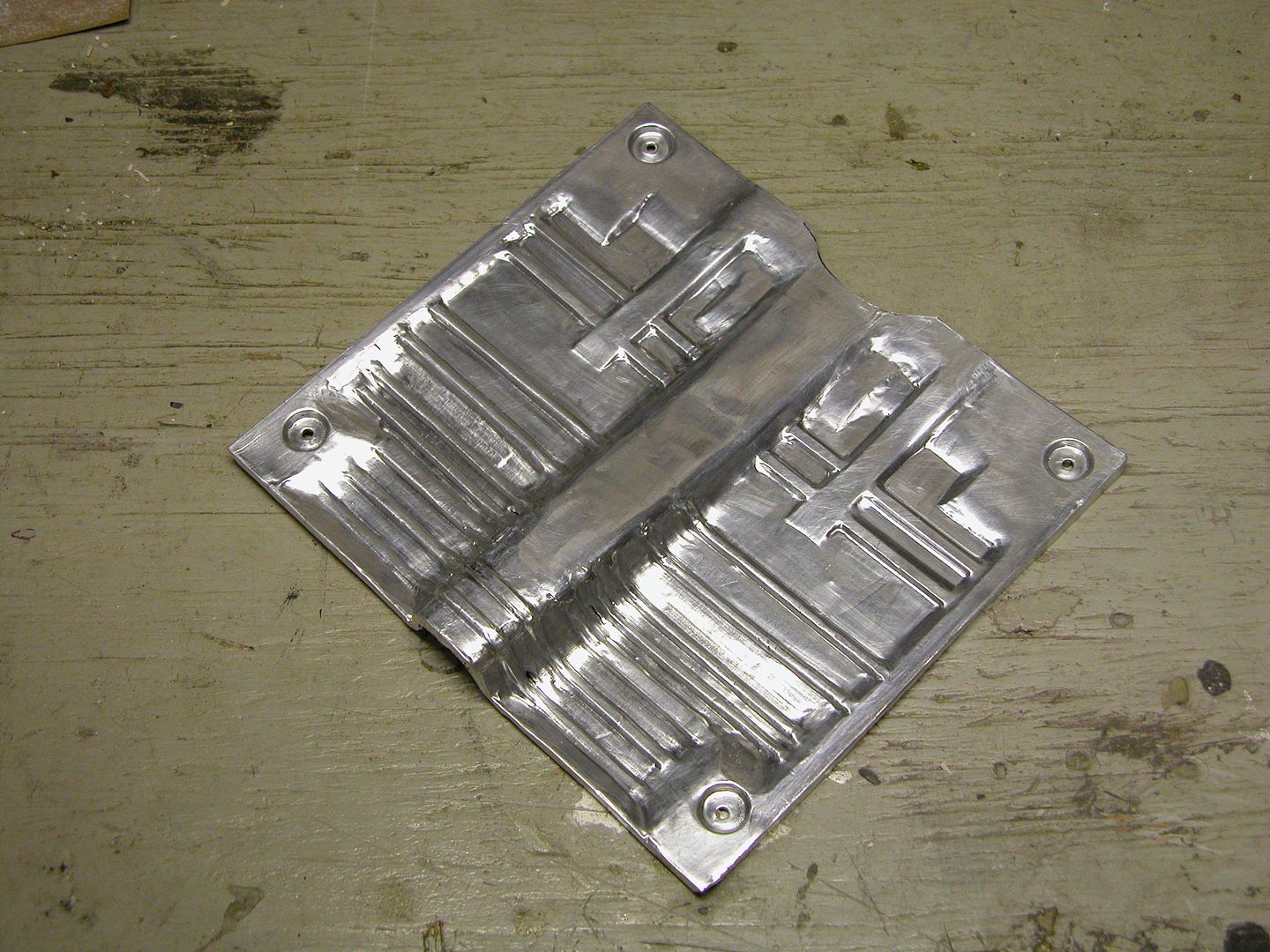

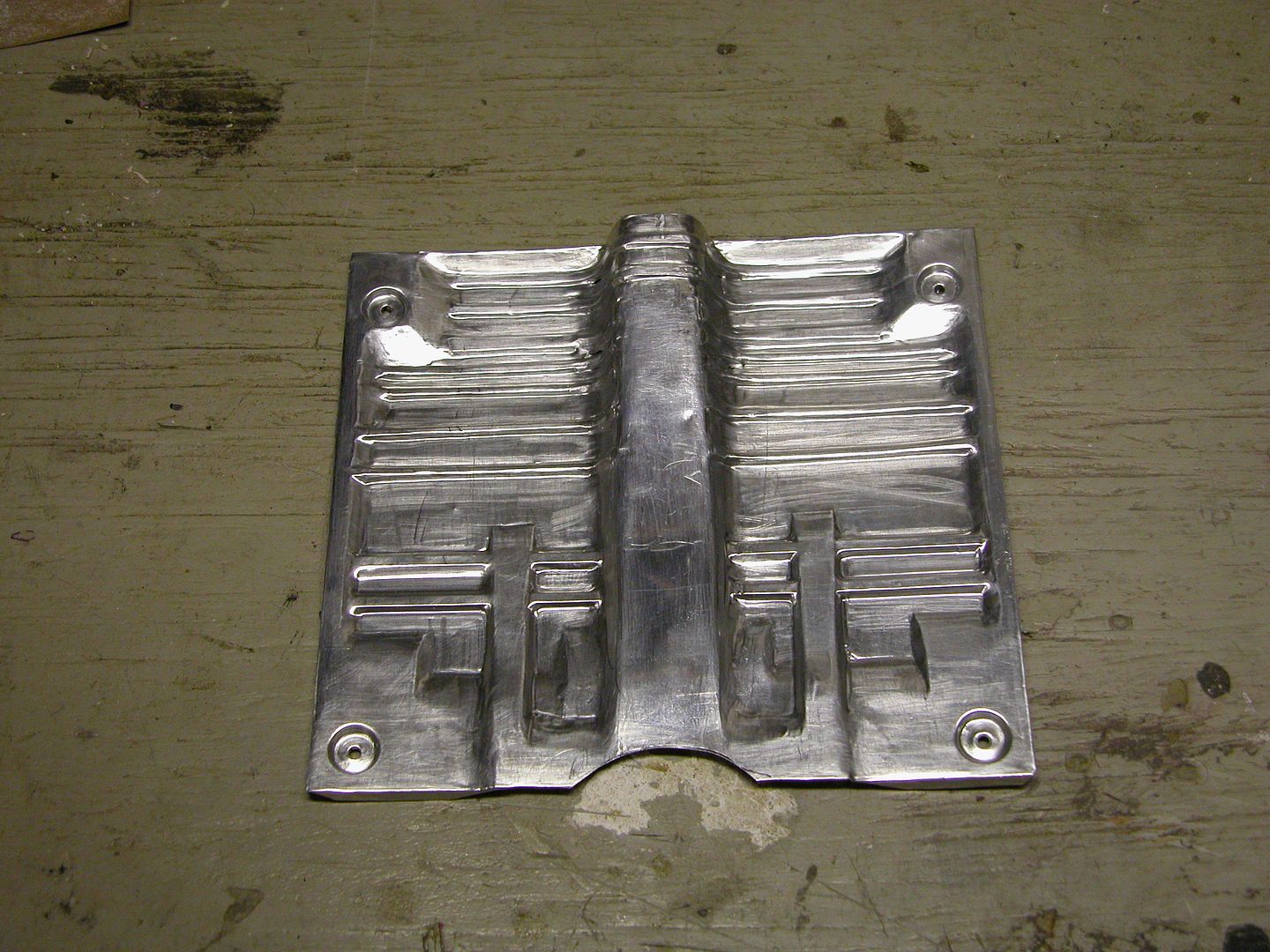

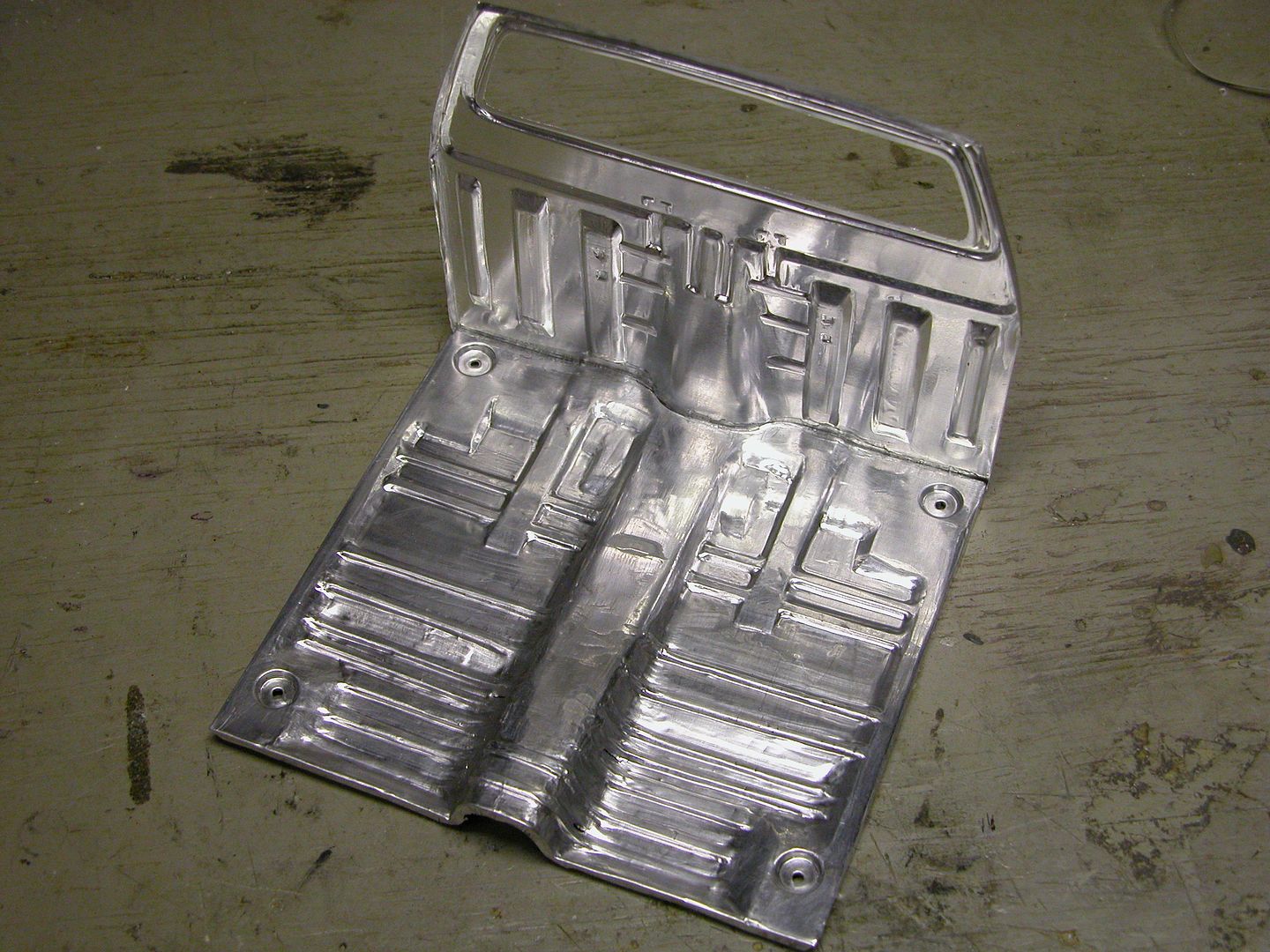

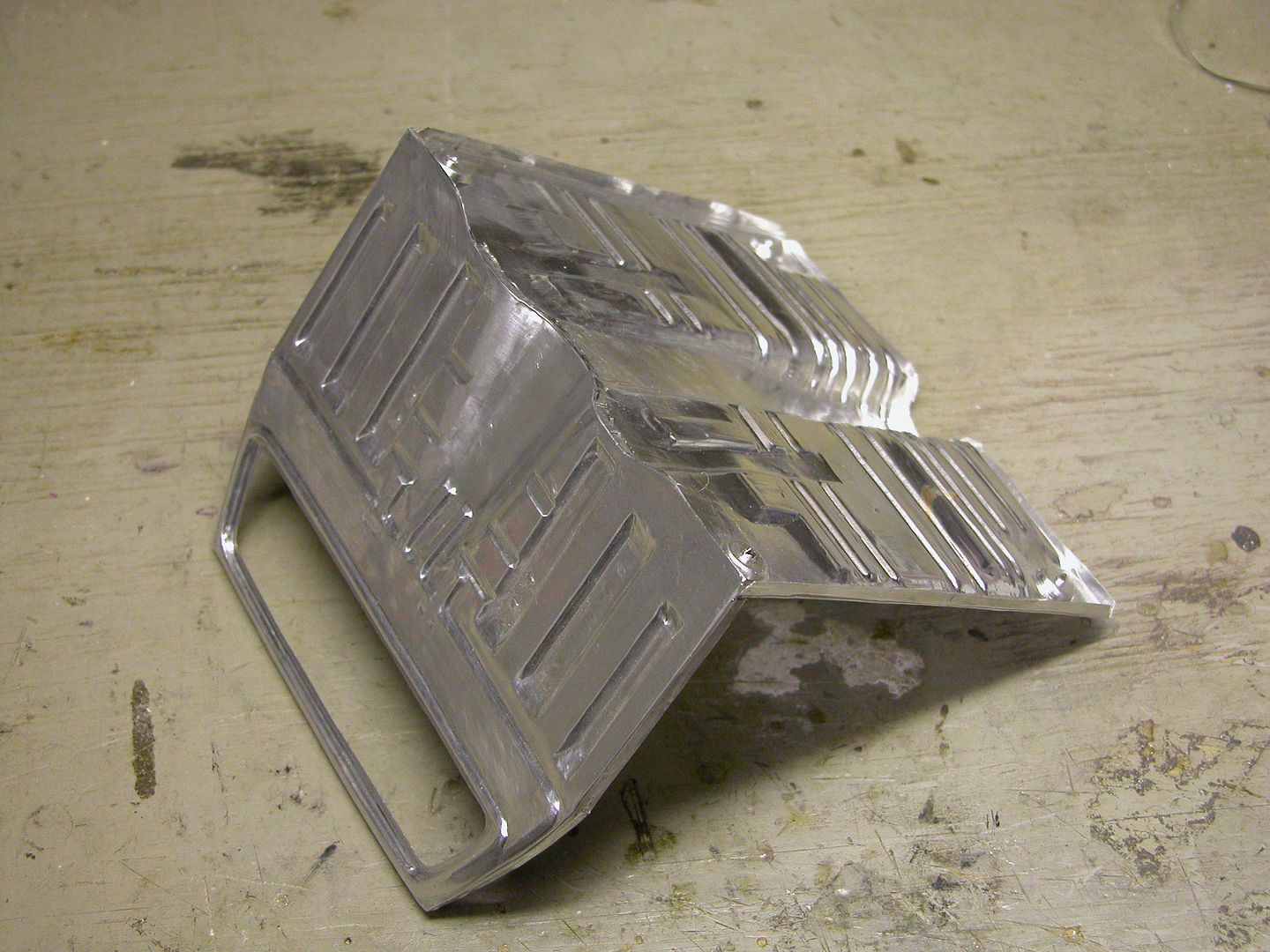

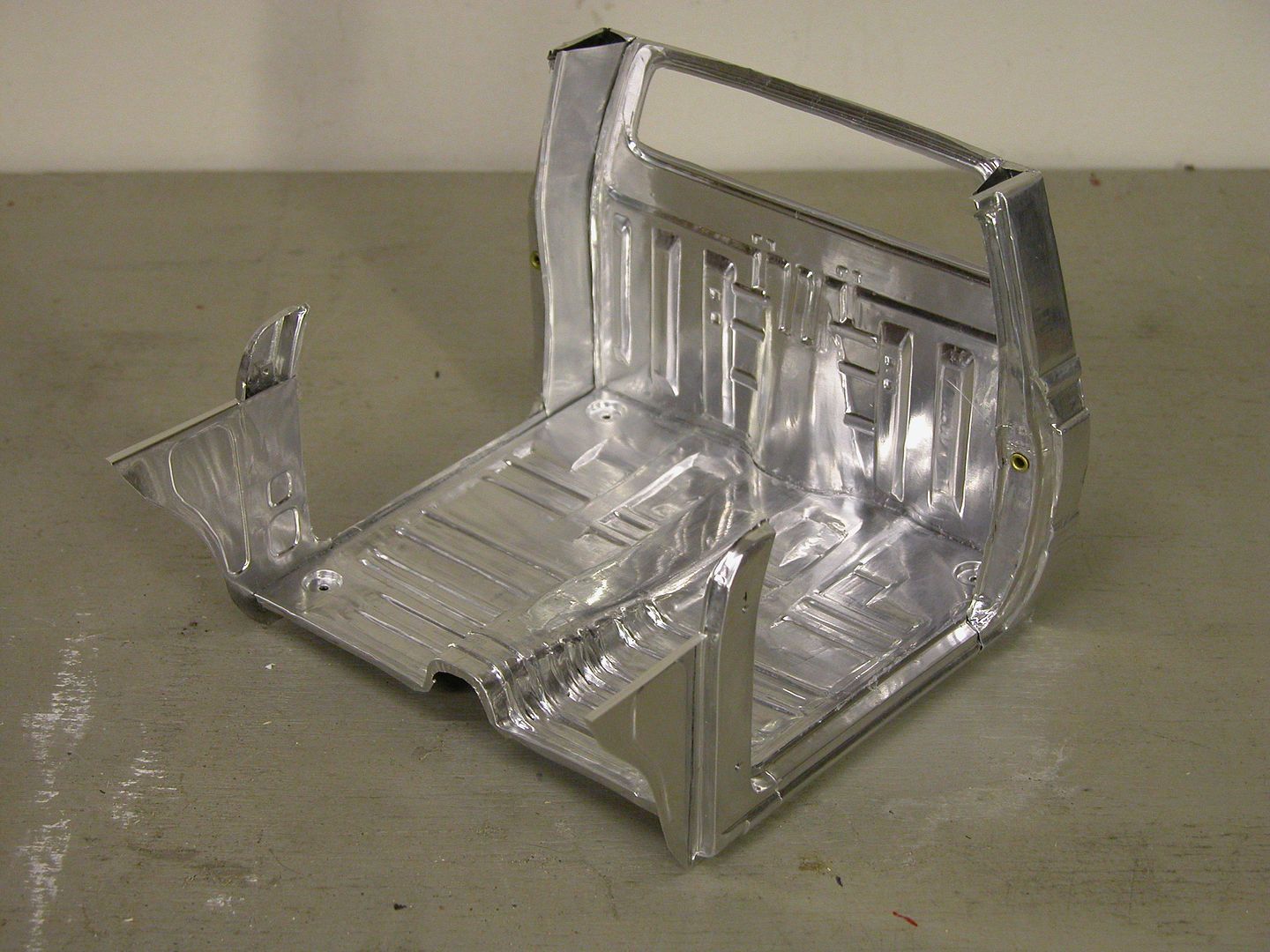

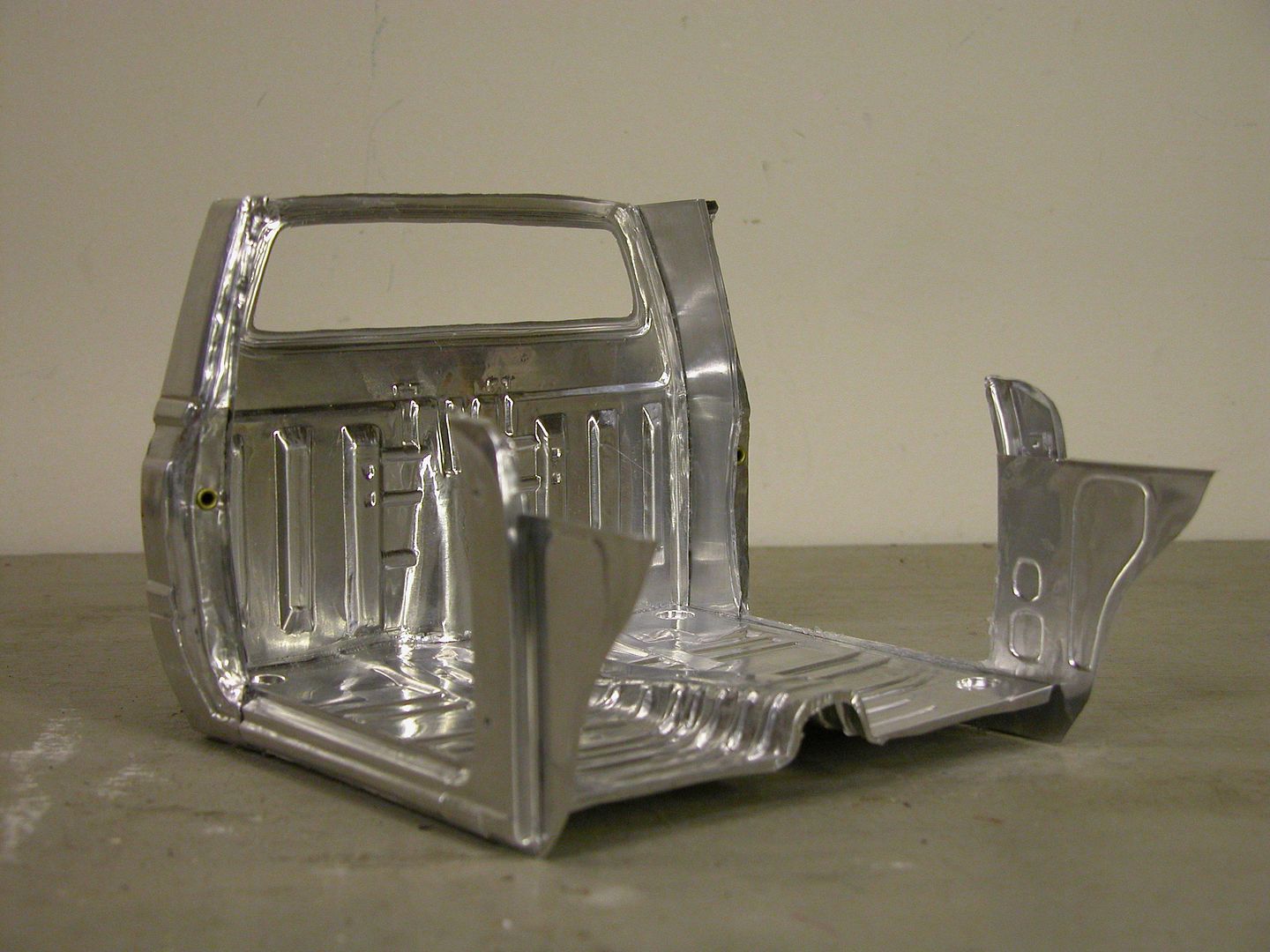

I know it's been a bit since my last update and i've been working hard on this to get more done. Once I had the outer rocker and cab corners assembled I needed to make inner panels to attach the floor to, so I made a simple mold for the inside of the rear cab corners  Then i made the panel for the inside of the A pillar that ties into the inner fender and cowl   Once they were done i need to prepare the outer panels with attachment points for the doors since it would not be accessible once the inner panels were assembled. I used the same technique as i did for the bed by drilling and tapping some small pieces of aluminum, punching holes in the panel and gluing them in place  And for the lower fender mount i simply glued in a small 2MM screw  Then i added a brass grommet to act as a door latch. You'll see how that works once i get the doors done  finally i glued the inner panels on    You would not believe how rigid the assemble became once the inner panels were in place. I could twist it almost 1/2" before and now it is rock solid! Next i finally finished the floor mold with all the added ribbing and the pockets for the cab mounts  and finished the floor panel   then i trimmed up the rear cab panel including the window and glued it to the floor   and of course glued all the parts together. I now have the beginning of a real cab!!     And in case anyone was wondering, the total molds I have made to date for this truck is 27! and i have about a dozen more to go Time for sleep. | |||

| |  |

| | #200 |

| Quarry Creeper Join Date: Feb 2008 Location: Irvine KY

Posts: 299

|

Wow. So, when it flips, how much damage do you expect? Looks great. |

| |  |

|

LinkBacks (?)

LinkBacks (?)

LinkBack to this Thread: http://www.rccrawler.com/forum/1-9-scale-rigs/147988-project-true-scale-aluminum-toyota-body.html | ||||

| Posted By | For | Type | Date | |

| Кузова,все о них и для них - Страница 5 | This thread | Refback | 10-05-2011 08:25 PM | |

| Wow, Amazing Scale RC Toyota - Tacoma World Forums | This thread | Refback | 10-04-2011 06:14 PM | |

| |