| | #61 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

I imagine you have quick change holders and set up offsets before running the program? It's no small feat to take a CAD file into a real product. Seems there is always something during manufacturing that wasn't thought of during design. I guess that is why machinists and design engineers aren't always the best of friends |

| |  |

| Sponsored Links | |

| | #62 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

|

I use tormach tool holders, most with er20 collets. I always seem to spend just as time setting up the tool paths for a part as it takes the machine to cut it, if not more time. Setting up the tool path to cut the locating notches in the soft jaw took some time, I ended up sketching a cut line in bobcad. Next time I will oversize the corner relief holes in solidworks. Then on the rim, cutting the notches on the backside required a sketch for the tool path as well. |

| |  |

| | #63 |

| owner, Holmes Hobbies LLC  Join Date: Nov 2004 Location: Volt up! Gear down!

Posts: 20,290

|

I'm in the same boat. Programming and tooling typically takes as long or longer than the first part. Heck, motor faceplates alone I have spent about 10 hours just in toolpath and workholding refinement, and a few more hours in the basic CAD files. 3.5 minutes to cut |

| |  |

| | #64 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

Nice work! I like the design touches too  |

| |  |

| | #65 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

|

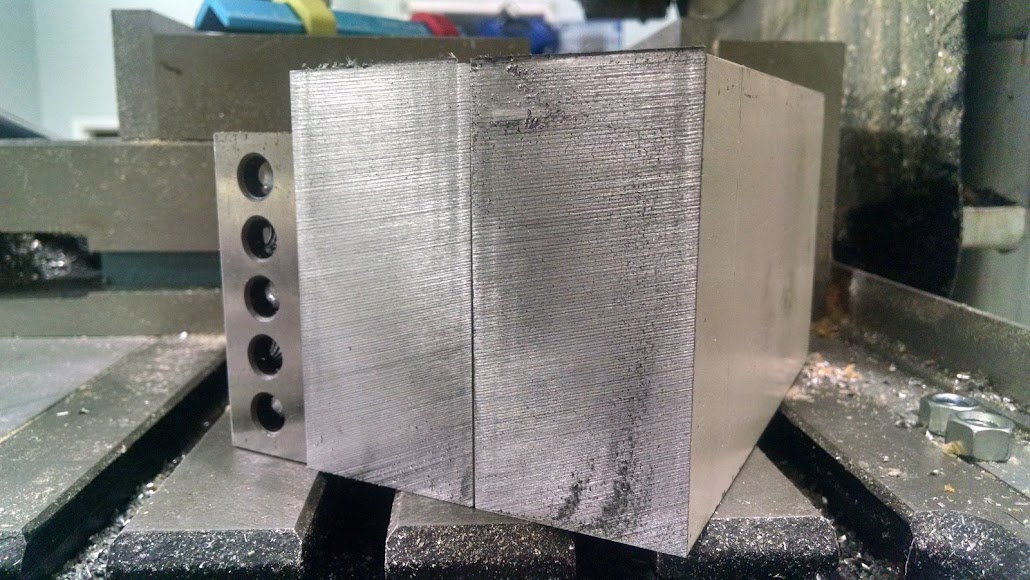

Thanks Rob Took a few pictures of the front side ops, as well as the soft jaws. The soft jaws worked out great, the little notch in the base does a great job of indexing the rims.  Putting a slight chamfer on the edges  |

| |  |

| | #66 |

| Suck it up!  Join Date: Mar 2008 Location: Arkansas

Posts: 11,652

|

Who's jealous? This guy. |

| |  |

| | #67 |

| RCC Addict Join Date: Aug 2013 Location: Calgary - in the Great White North

Posts: 1,373

|

Not me, nope not at all. |

| |  |

| | #68 |

| Rock Crawler Join Date: May 2012 Location: Minneapolis

Posts: 858

|

Are those for the Yeti or what?

|

| |  |

| | #69 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

| I'm jealous of your etch-a-sketch skills on the rong fu  Sure are, they use the stock back ring and inner beadlock ring. I found out that the problem with the stock wheels loosing a bead is from the inner beadlock ring flexing. I just picked up some PVC couplers tonight, and chucked one up in the lathe. I narrowed the coupler, then bored either side to fit the stock ring. Then I slit the ring with hacksaw, and slipped it over the stock ring.  opened up profile, its a tight fit.  and squeezed together.  I couldn't pull my voodoo U4 tire out, easy fix  Now I need to make 3 more. Now I need to make 3 more.

|

| |  |

| | #70 | |

| www.ottsix.com Join Date: Mar 2011 Location: Albuquerque, New Mexico USA

Posts: 2,050

| Quote:

| |

| |  |

| | #71 | |

| Rock Crawler Join Date: May 2012 Location: Minneapolis

Posts: 858

| Quote:

Voodoo U4 tires...someone is definitely sick of getting whooped by me in the U4 races Looking forward to seeing these wheels in person. Dna | |

| |  |

| | #72 |

| Pebble Pounder Join Date: Oct 2007 Location: Star Prairie, WI

Posts: 165

|

Nice addition to your shop! Your wheels look good too! Nice work man. |

| |  |

| | #73 |

| I wanna be Dave Join Date: May 2007 Location: Fairfield ME

Posts: 3,886

|

What keeps the PVC ring closed?

|

| |  |

| | #74 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

|

They are a press fit, and they also want to return to their closed state. But I think I will be making some aluminum inserts pretty soon. The PVC clamps weigh as much as my aluminum rim faces |

| |  |

| | #75 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

|

Havent touched the mill in a few months... Last fall I put some new casters on it, so I could move it around the shop easier. Then I painted my garage floor, and started looking into rewiring the control box on the mill. After months of procrastinating, I pulled the trigger on updating my controls to the latest version of Centroid CNC11. This involved a new PLC, and a new computer. A few of the benefits from this are - Ability to run on windows 7 or 8 - USB!!!!! No more 3.5" floppy disks - Ethernet file transfer - WCS (6 locations) - The only connection between the PC and PLC will now be a single ethernet cable, before I had 4 stiff and short fiber optic cables, along with all 3 encoder cables running into the back of the pc. Here is how the new control box sits as of right now.  Working on wiring layout now, just trying to figure out where the AC and DC voltage runs need to go. The upgrade kit included some very complete wiring diagrams. |

| |  |

| | #76 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

|

Progress has been slow, but I think I finally figured out how I am going to route my cables. I picked up a cable entry block at a local automation surpluses store. I will feed my servo power leads, encoders, PC Ethernet, and control panel data cable through this block. I have a couple smaller blocks as well, which I will use for the limit switches.  Picked up a cord cover for the cables, still working out how I want to handle the cable management.  And I have started on the wiring, but the manual states that I should test my encoders next before wiring anything else. So I need to finish punching holes into the enclosure, and routing all of the cables that run into the enclosure. Then I will run power to it and continue setting it up.  |

| |  |

| | #77 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

Ballpark price for the new controls? It's got to be a pretty reliable setup. Pm me if you want.

|

| |  |

| | #78 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

|

Pricing is on their site Ajax CNC – CNC Retrofit Control Systems for Milling machines, Routers and Lathes. Runs CENTROID Software upgrading to their newer version was basically the cost of the allin1dc board without cnc11, since I already owned their software. It is a very reliable system, with this old controls I never had the software crash.

|

| |  |

| | #79 |

| I wanna be Dave Join Date: Oct 2004 Location: QC-AZ

Posts: 2,352

|

Nice. If I ever do another machine it will have a more professional control system such as that. Looking forward to seeing more updates!

|

| |  |

| | #80 |

| Web Wheeling  Join Date: Jan 2005 Location: Twin Cities

Posts: 3,004

|

Worked on the mill for a couple hours tonight. One of the parts of the mill I decided to rework during this upgrade, was the Z axis couterweight system. For one, it had more weight then what was needed, and even more so after upgrading to a belt drive system. Second, I did not like how wide it was, with 2 large concrete blocks hanging off either side of the mill. I pulled the concrete blocks off about a month ago, and picked up some steel plates to use as weights. I've been staring at the cross bar, contemplating if I should cut it down as well, as it was now in the way of my new power feed. I finally pulled the crossbar off tonight, and tossed it in the bandsaw.  added a clamp to keep the drop from hitting the floor, each cut took about 14 minutes.  Here are the two drops next to a 123 block for comparison, the cuts are pretty damn square. I love cutting thick solid steel with this saw.  And here are the steel plates I will be adding. I will only be using 10 of them, cutting 2 in half. Then bolting half on each side of the bar.  This should give me a total weight of just under 160lbs. The old setup was around 250lbs. And from what I have read online, the head weighs 75kg(165.347lbs). Also ran my limit switch wiring into the box, still need route and secure the wires inside the box.  And a updated picture of the inside of the box. I also pulled the power cord into the box.  I might move my PLC over to the left a bit, with my signal wires coming in from the front of the box it is getting a little tight over on the right side. I am going to try to finish up a little more wiring, and power up the PLC this weekend. And hopefully get the servos and limit switches running properly, then I will tackle the VFD. |

| |  |

|

New toy for the shop, CNC Mill - Similar Threads

New toy for the shop, CNC Mill - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| CNC Router/Mill by Shapeoko | 89redranger | Tools, and Procedures | 15 | 06-30-2013 09:22 AM |

| Anybody have any experience on a minitech cnc mill/2? | klabeaume | Tools, and Procedures | 2 | 07-27-2012 02:27 PM |

| CNC Mill on the Cheap. (colorado) | dezrik | Chit Chat | 0 | 12-06-2008 08:40 AM |

| Pics of my new cnc mill. | BENDER | Tools, and Procedures | 18 | 11-22-2007 12:38 AM |

| Taig CNC mill | bret4 | Tools, and Procedures | 6 | 09-22-2006 01:54 PM |

| |