| | #121 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

|

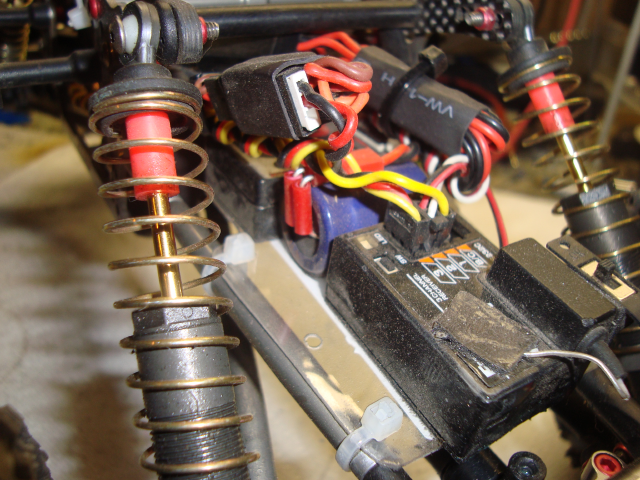

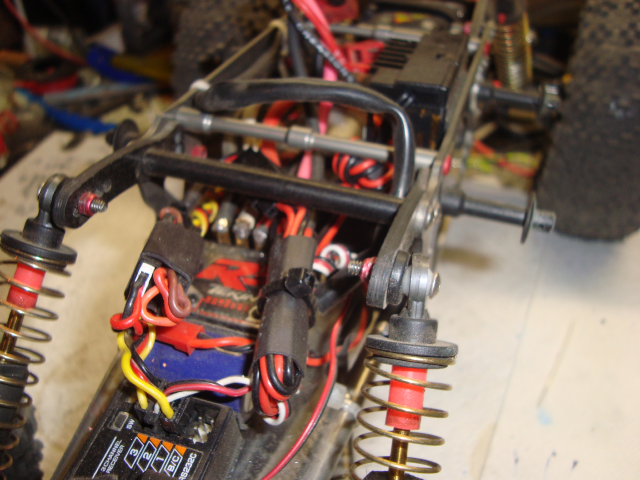

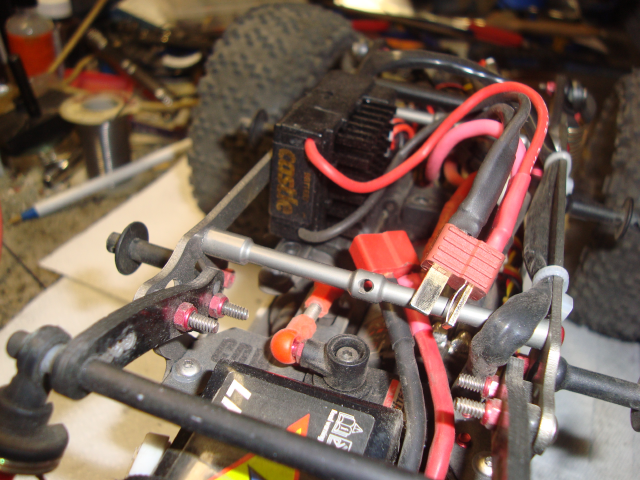

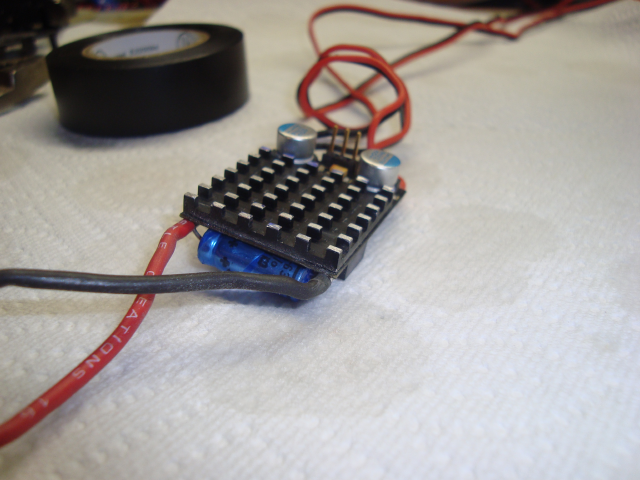

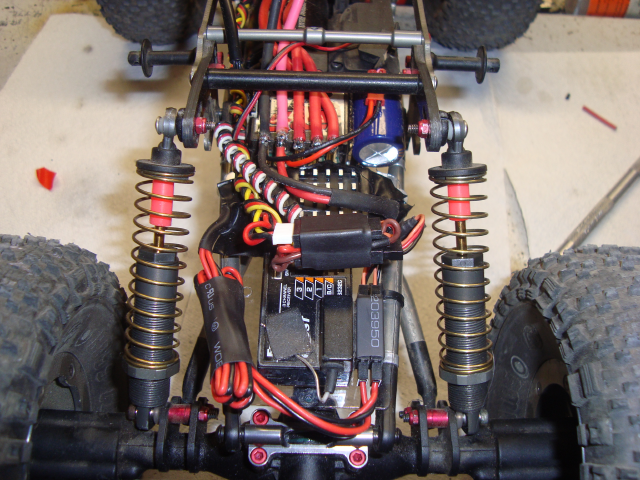

thought Id post some pics of my bec for those who have read the problems I was having. So far the CC BEC Pro has been hanging in there and so far hasnt shown any problems. So where do you stuff an esc sized bec on a rig with little space left? nope not in this mess  ahh this will work for now    It works there for now but will be redone once my two winter series are done. Also a shot of my current Boss Claws.  I feel like I lost a little of my forward bite compared to my original set but my sidehill/off camber situations feel much better now. Very pleased with overall performance of this cut for me. Other then that the rig is still working great  |

| |  |

| Sponsored Links | |

| | #122 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

|

That's ridiculous! And I'm not talking about your tire cut. |

| |  |

| | #123 |

| Rock Crawler Join Date: Oct 2008 Location: Sandy, OR

Posts: 672

|

Wowee, that thing has some size to it, doesn't it? I was thinking about getting one, but damn that's big.

|

| |  |

| | #124 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Tell me how ya really feel Ya Im on the alternative hunt now, even the wiring has me buggin out its so messy. Yup I wasnt kidding when I called it a 'toaster oven' in the bec thread, even guys at the comp thought it was a sidewinder esc. |

| |  |

| | #125 |

| Quarry Creeper Join Date: Dec 2010 Location: Hector

Posts: 254

|

You guys inspire me : Thanks for sharing, Good reading  |

| |  |

| | #126 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

| |

| |  |

| | #127 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| |

| |  |

| | #128 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

|

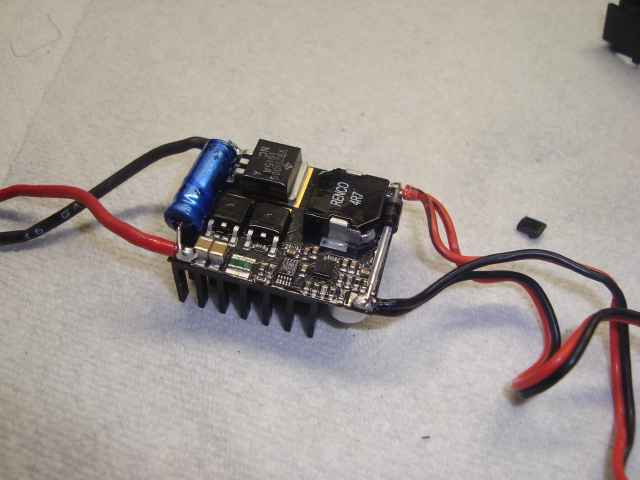

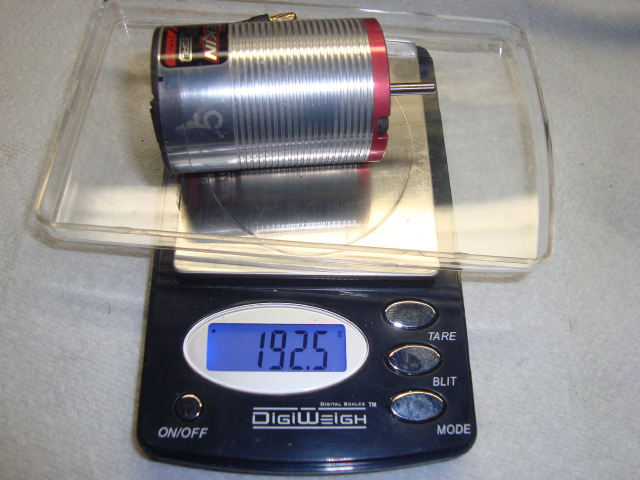

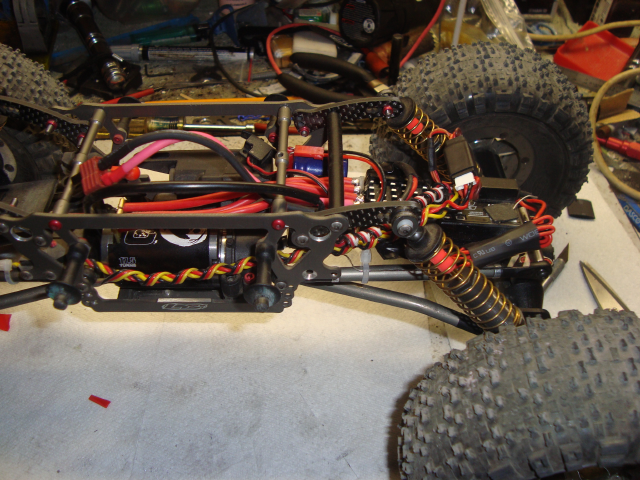

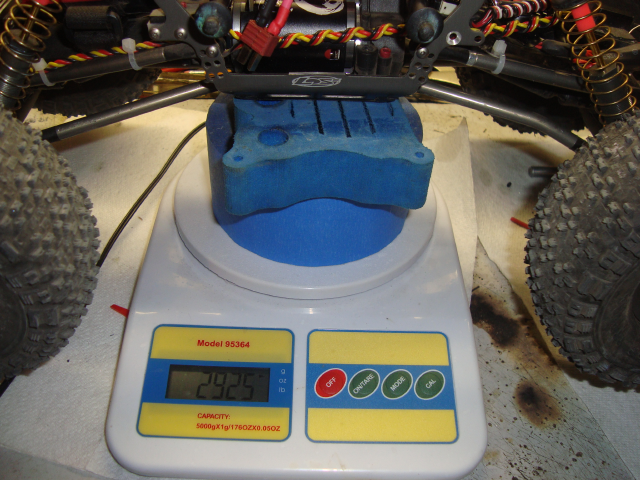

So a little update to the trucks current setup ..... Front: Shock Oil - 55wt Spring - Losi Gold External limiter - 17mm Piston - Losi #55 Shock Location - #5 Arm Location - B Rear: Shock Oil - 30wt Spring - Losi Gold External Limiter - 17mm Piston - Losi #57 Shock Location - #4 Arm Location - C Weight w/out Body: 2953grams/6.51lbs   well been running a bit now with the CC BEC Pro and havent had any problems yet so it was time to try and straighten a few things out. Stock BEC Pro  And heres me 'taking one for the team'   And a little more weight loss  This was also a perfect time to try a new motor ...... Trinity D3 17.5 w/Sintered rotor  Weight comparison Tekin Redline 17.5 w/13mm HT Rotor  Trinity D3 w/out banana plugs  The fun of wiring    Total weight again w/out body 2925grams ...... lost 28grams  |

| |  |

| | #129 |

| RCC Addict  Join Date: Jun 2005 Location: St. Albans

Posts: 1,441

|

Holy wiring diagram Batman!! I cant believe you squeezed all of that onto the rear links.

|

| |  |

| | #130 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

|

Got to run the D3 last week and so far very pleased with it. I started with the same RS setup and 13T pinion I been running on the Redline. From the start I could feel an increase in Torque with some decrease in temps after a run. Wheel speed felt about the same but I did gain some low end snap off the start. I tried going up in pinions, my LHS only had a 16T as the lowest so said what the heck and went for it. Wheel speed was a great gain ofcourse but I knew that big of a jump had downsides. Motor was hotter then I felt comfortable with so waiting for my 14 and 15T pinions to come in. Im thinking a 14T would be the better choice. Overall with the 13T Im very pleased with the motor swap, gonna throw a 14T for next practice. Im also planning to try some motor timing, since its still at 0*, with both the 13T and 14T pinions for next practice. Current RS settings: Motor Type: Brushless w/instant reverse Voltage Cutoff: 3S Motor Direction: Reverse (since tranny is flipped) Throttle Profile: 3 Current Limiter: Off Drag Brake: Off Minimum Brake: 0 Minimum Throttle: 15 Brake Strength: 0 Reverse Speed: 100 Neutral Width: 10 Push Control: 0 Boost: 30 - starting @ 5443 ending at 20000 Ill post up after I try the gearing and timing changes  |

| |  |

| | #131 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| |

| |  |

| | #132 |

| MODERATOR™  Join Date: Jul 2004 Location: Ohio

Posts: 18,928

| |

| |  |

| | #133 |

| RCC Addict Join Date: Dec 2009 Location: Newcastle, Australia

Posts: 1,784

|

Thats a big ass cap on your esc, any reason for that??

|

| |  |

| | #134 |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| I was just gonna wrap it all around the cross brace but that idea was already used We use to run multiple ones (3 smaller 1000uf 16v) in TC to take some heat off the esc and load off the batteries from throttle bursts exiting corners and brake spikes when we did use them. I got to thinking even though we run slower and smoother it could still help. Im thinking it may help with bursting the battery and load we may put on the esc when stabbing the throttle, or in my case when I roof the truck and rip the throttle/reverse to upright myself. Cant say it shows any improvements using it but surely hasnt hurt anything. |

| |  |

| | #135 | |

| RCC Addict Join Date: Dec 2009 Location: Newcastle, Australia

Posts: 1,784

| Quote:

| |

| |  |

| | #136 |

| Rock Crawler Join Date: Oct 2008 Location: Sandy, OR

Posts: 672

|

Robbob - I am interested in how you are powering your servo and receiver off the Pro BEC. Are you running one lead directly to the servo and the other to the receiver? Also, how do you have the signal and ground wires set up? I am getting one of these tomorrow to hopefully alleviate my BEC troubles. I received a brand new 10A BEC from Castle on Thursday, installed it just like the one that is in it, and it lasted all of 10 minutes before it went out. The light on the BEC was still on but it was only putting out 2.5V. I put my old BEC back in exactly the same and went about my business. It still cuts out occasionally, but at least it is working. I am calling Castle tomorrow to try to get this done and over for now. I have two dead BEC's that have a total of about 10-15 minutes on them. I am hoping they will trade them out for Pro BEC, or at least give me two more that I can have for spares or to sell. I did spend an hour today pulling my servo completely apart and checking everything. One of the bearings on the main drive gear is a little rough, so I lubed it up really good, greased all the gears, and put it back together. I don't think it is rough enough to make a difference in the amp draw, but maybe it could be part of the problem.

|

| |  |

| | #137 | |

| Custom Carbon Fiber  Join Date: Oct 2007 Location: Connecticut :(

Posts: 4,501

| Quote:

I wired it basically the same way we all been doing it, red wire on the esc still plugged in. Using the bec from the esc to power the rx/esc/dig servo. Servo signal gos into the RX Y-connector used ......... the two leads coming out of the Pro plug into that ....... Servo red/black wires go into the single plug of the y-connector. Grounded through the battery. I will say when I unplug the battery the light stays on for a few seconds until the capacitor discharges. That part I dont like but the only way I can fix it is wire the servo and Pro grounds through the RX. If I plugged the blue bex into the rx I can only set it @6v. Thats max the Futaba will take and the servo causes the system to brown out. I never bothered pluggin the Pro into the rx for the same reason, can only run 6v into the rx. Im gonna get some 18g wire this week and redo the output wires on the Pro. Single red/black wires into some mini deans into the servo leads. | |

| |  |

| | #138 |

| Rock Crawler Join Date: Oct 2008 Location: Sandy, OR

Posts: 672

|

Got it. I only run my servo at 6.0 V, so I was thinking about running one lead on the Pro BEC to the servo and the other into the receiver to power it and the dig. I guess I will figure it out when I get it tonight. I really hope this fixes my problems, this is getting beyond annoying. My BEC cut out yesterday at exactly the wrong time, costing me at least a course win and probably the overall win. |

| |  |

| | #139 |

| Rock Crawler Join Date: Jul 2010 Location: VOLS!

Posts: 564

|

The D3 sounds promising! Will be keeping up to see how the changes work out... Thanks for going through the trouble  |

| |  |

| | #140 |

| Rock Crawler Join Date: Jul 2010 Location: VOLS!

Posts: 564

|

Have you been able to get any more time on the d3?

|

| |  |

|

| |