| | #141 |

| Rock Crawler Join Date: Apr 2011 Location: Sonoma County

Posts: 517

|

I noticed that the rear axle has a lot of play left to right. I think it has to do with my rear shock placement being so wide. It can move maybe 1/2" to an 1" from side to side. Is this normal? Good? Bad? The front axle doesn't have play like the rear.

|

| |  |

| Sponsored Links | |

| | #142 | |

| Rock Stacker Join Date: May 2010 Location: Sydney/Australia

Posts: 60

| Quote:

moving shocks wont do much. it is most likely because your upper links are too parrallel to one another. can you get away without having those spacers on the chassis side of your links?. if not then put some spacers in between the back to triangulate the uppers like this _\ /_ a bit more. should reduce it somewhat. | |

| |  |

| | #143 | |

| I wanna be Dave Join Date: Jan 2006 Location: ...the burning end of the rope.

Posts: 5,013

| Quote:

Thomas | |

| |  |

| | #144 | |

| RCC Addict Join Date: Mar 2007 Location: Turn the mayflower around.. it will never work

Posts: 1,588

| Quote:

And so on to the reason I read 8 pages..... and didnt see it posted once: More pics of said chick with no wedding ring. After page one I was let down tremendously with lack of these photos. The build was going "good" almost "too good"  Last edited by JokersWild; 08-03-2011 at 10:33 AM. | |

| |  |

| | #145 |

| Rock Crawler Join Date: Apr 2011 Location: Sonoma County

Posts: 517

|

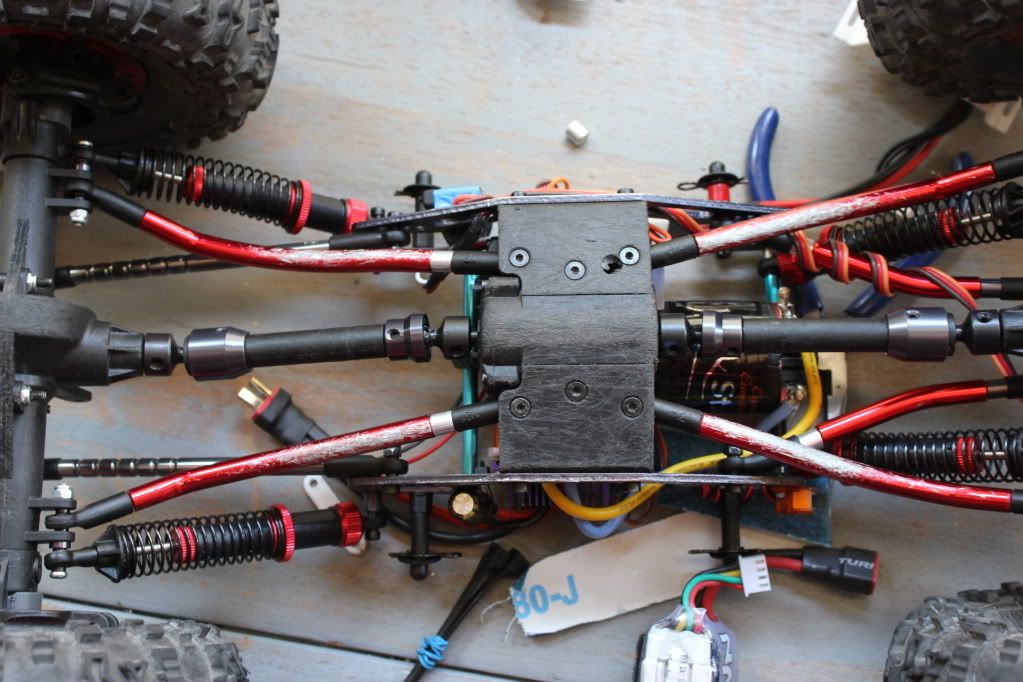

I installed the driveline update parts. I had to cut down the inner shaft a little bit. The pin covers on the larger shafts don't fit over the pins all the way... It's over 1/2 of the pins though so that should be enough.   |

| |  |

| | #146 | |

| I wanna be Dave Join Date: Jan 2006 Location: ...the burning end of the rope.

Posts: 5,013

| Quote:

| |

| |  |

| | #147 | |

| Rock Crawler Join Date: Apr 2011 Location: Sonoma County

Posts: 517

| Quote:

I adjusted the links to be a little more triangulated:   | |

| |  |

| | #148 | |

| RCC Addict Join Date: Mar 2007 Location: Turn the mayflower around.. it will never work

Posts: 1,588

| Quote:

| |

| |  |

| | #149 | |

| Rock Crawler Join Date: May 2010 Location: CRAWlORADO

Posts: 950

| Quote:

| |

| |  |

| | #150 |

| I wanna be Dave Join Date: Jan 2006 Location: ...the burning end of the rope.

Posts: 5,013

| |

| |  |

| | #151 |

| I wanna be Dave Join Date: May 2010 Location: The east coast

Posts: 2,599

| |

| |  |

| | #152 |

| I wanna be Dave Join Date: Jan 2006 Location: ...the burning end of the rope.

Posts: 5,013

| SOme amount of roll center is necessary to lock the chassis between the axles...but the further behind the rig you can get the roll center the better the TT effect is. And I dont debate 1:1 vs. scale at all because first of all my Creeper axles wont carry a 600 lb rc chassis...and if my calcs are correct the tires would have to be air tight and inflated to about 5.5psi for decent traction on rocks. The amount of torque generated by a 6 lb rc in relation to its weight requires more link geometry spread based on the power to weight ratio.

|

| |  |

| | #153 | |

| Rock Crawler Join Date: May 2010 Location: CRAWlORADO

Posts: 950

| Quote:

| |

| |  |

| | #154 |

| Rock Crawler Join Date: Apr 2011 Location: Sonoma County

Posts: 517

|

New Battery placement up front:   |

| |  |

| | #155 |

| Rock Crawler Join Date: Apr 2011 Location: Sonoma County

Posts: 517

|

Putting the Batt in the front made a ton of difference. Then I tore a pin out of the driveshaft.  |

| |  |

| | #156 |

| I wanna be Dave Join Date: Jan 2006 Location: ...the burning end of the rope.

Posts: 5,013

|

Did you break it on rocks at least?

|

| |  |

| | #157 |

| Rock Crawler Join Date: Apr 2011 Location: Sonoma County

Posts: 517

| |

| |  |

| | #158 |

| I wanna be Dave Join Date: Jan 2006 Location: ...the burning end of the rope.

Posts: 5,013

| |

| |  |

| | #159 |

| Rock Crawler Join Date: Apr 2011 Location: Sonoma County

Posts: 517

|

The TT is much better now. Adding the spacers on the back helped a lot, I'll add some more when I get some. It broke when I got stuck in a hole and gave it too much power. The pin covers on the shaft only fit over 1/2 of the pin so I think that the only place the pin to go was through the plastic. The pin cover could have been pressing against the pin... Should I just get the Traxxas long truck shafts or try to find just the plastic parts of the venom shafts? I'm guessing the Traxxas shafts that people are using would last longer... |

| |  |

| | #160 | |

| I wanna be Dave Join Date: Jan 2006 Location: ...the burning end of the rope.

Posts: 5,013

| Quote:

| |

| |  |

|

| Tags |

| 3d print, build, creeper, step by step, venom |

| |