| | #121 |

| RCC Addict  Join Date: May 2010 Location: Midwest

Posts: 1,917

|

I'm not sure what you mean. What do you think the rig will do exactly?

|

| |  |

| Sponsored Links | |

| | #122 | |

| I wanna be Dave Join Date: Oct 2007 Location: Castle Rock, WA

Posts: 8,785

| Quote:

Not tyring to highjack, just that I have had to work around the SCX and Wraith skid link geo setups. | |

| |  |

| | #123 |

| RCC Addict  Join Date: May 2010 Location: Midwest

Posts: 1,917

|

Don't worry about thread jacking., this is tech advice/suggestion. What do you see about the rear link setup? Its just custom bent scx10 geometry really. Is it the bends that might cause issues? I have weighted front wheels. Also, I plan to make a single bump stop incorporated into the chassis for the rear axle to limit its up travel when both wheels move up at the same time but, it will be a single pivot point that will bump off of the center of the rear axle housing, it will still allow suspension articulation but, limit up travel when the axle is straight. I'm doing this to keep the axle out of my fuel cell & accessory box but, it sounds like this might help the above mentioned situation as well. What do you think? |

| |  |

| | #124 |

| I wanna be Dave Join Date: Oct 2007 Location: Castle Rock, WA

Posts: 8,785

|

Really there needs to be less separation of the links at the rear axle but you can't really change that. So, the only other option is to raise them at the chassis. You would have to make some new mounts on the chassis to do it. Like so |

| |  |

| | #125 |

| RCC Addict  Join Date: May 2010 Location: Midwest

Posts: 1,917

|

Hmm.. Ok, I'll see what I can come up with. It definately sounds like it could benefit me and not at all make it worse. I should be able to fab a little bracket that will allow me to mount my links higher like that. Thanks.

|

| |  |

| | #126 |

| I wanna be Dave Join Date: Jun 2008 Location: Sin City

Posts: 3,628

|

When you look from the side you want the links parallel to each other as much as possible. Top vs bottom. That is my best starting point for ya But in saying that there is more going on than a 1:1 IMHO. Weight is different, power 2 weight, torque, direction of links at ride height: They all play a big part. It comes down to personal preference. I crawl with guys that make the scx10 layout work as well as my setups. If you have time, play with it. If not wire her and drive it. Knowing your rig 100% of the time will be better than a last min test drive before a comp. |

| |  |

| | #127 |

| I wanna be Dave Join Date: Oct 2007 Location: Castle Rock, WA

Posts: 8,785

|

Yep to what Double J said. I was just putting it in your ear before you got too far along in the fabrication. Suspension tweaking options are always a good thing, if you ask me. |

| |  |

| | #128 |

| RCC Addict  Join Date: May 2010 Location: Midwest

Posts: 1,917

|

I kicked some ass again tonight.. First of all.. A continuation from earlier today when I showed you my dual shock mount brackets I made.. here's what the dual shocks look like. I'm really diggin' it. It gives that Ultra4 look.   Next.. I took doublej & Szczerba's advice and change my rear upper link mounts to a higher position. I cut through a section of rod to install a tube sleeve & brazed it in. Note: my pointer is showing the previous rear upper link mount position and the tube I'm brazing in is the new position.  and.. stuck on.  We'll see what happens with that. I trust their judgement. Here's a few pics of the new link setup..     ........ |

| |  |

| | #129 |

| RCC Addict  Join Date: May 2010 Location: Midwest

Posts: 1,917

|

....... Ok.. next. I was talking earlier about making a chassis mounted bump stop system that would only bump stop the center of the rear axle to keep the axle away from my fuel cell, etc. So, the goal was to only limit the axles up travel when the axle is straight yet, allow it to articulate. anyways.. I did it. I made a piece, drill & tapped it for an M4 screw.. put a little rubber doo-hicky on there (that looks like a scale red polyurethane bump stop) and a M4 nut for locking the adjustment. Then I brazed it all in along with a few braces.  It seems to do exactly what I hoped it would do...    It still passes the spare tire test like before...  Here it is from the rear at ride height with the new bumpstop setup..  Here it is at full compression (axle straight)..  and here's a picture from yesterday without the bumpstop at full compression..  I'm happy with today's work. The next few things on my list are: -design/fabricate servo which line tube -design/fabricate servo winch mounts |

| |  |

| | #130 |

| Quarry Creeper Join Date: Nov 2012 Location: spanish fork

Posts: 435

|

Talent, I'm jealous of this rig!

|

| |  |

| | #131 |

| I wanna be Dave Join Date: Jun 2008 Location: Sin City

Posts: 3,628

|

looking good mate - keep it up.

|

| |  |

| | #132 |

| I wanna be Dave  Join Date: Dec 2009 Location: Outside DC

Posts: 2,997

|

Excellent engineering there! Keep bringing it! Very sharp work for sure. |

| |  |

| | #133 |

| RCC Addict  Join Date: May 2010 Location: Midwest

Posts: 1,917

|

Well, it was "panhard" night tonight. a shout out to my boy badhoopty for opening up the text lines to give tips/tricks/advice on panhard bars. I think it turned out pretty good.. here's what I ended up with for now.    As you can see, I'm using the VP axle mount. I fabbed up a little draglink chassis side mount and drill & tapped it fro M3 and tacked it on. I removed the axle truss and 1 front upper link to run 3-link. I was advised to use the upper link that is on the same side as the axle mount and also have the axle mount on the same side as the drag link so, I did all of that. I also kept the panhard bar & drag link similar lengths and on similar angles. One thing you cannot see is, I limited the front shocks down travel because there was ALOT of droop happening out front..to the point where it was causing weird things to happen to the steering when the chassis was that far away from the axle. anyways.. I seemed to fix that. I tried to use the longest servo horn I could to help with the gobs of droop as well. The drag link kinda sits a little behind the tie rod and the panhard is parallel to the axle. ride height: (not sure why its all crooked in the pic)  full compression:  full droop:  what do you guys think? |

| |  |

| | #134 |

| RCC Addict  Join Date: May 2010 Location: Midwest

Posts: 1,917

| |

| |  |

| | #135 |

| RCC Addict Join Date: Aug 2010 Location: wherever paypal sais.

Posts: 1,740

|

Lookin good rick!

|

| |  |

| | #136 |

| I wanna be Dave Join Date: Jun 2008 Location: Sin City

Posts: 3,628

|

This may be hard to understand - if so let me know and I will just call ya. Whats the measurement from ground to eye of the drag link and axle panhard? And same with frame mounts - All at ride height? ANd you said the drag and panhard are different lengths - how different and what stop you from making them the same? The "weird things to happen" is most likely caused by these things. I prefer as much flex and droop as possible in the front. Most say I am crazy but when you go over a steep break over like we have a lot of in Vegas - Droop is the only solution and I always want more. I have yet to have it hender me other places. As always just my 2cents - gimmie a PM if I am confusing. RC and 1:1 suspension design is as fun as metal design and engineering. |

| |  |

| | #137 |

| I wanna be Dave Join Date: Oct 2008 Location: Golden

Posts: 2,588

|

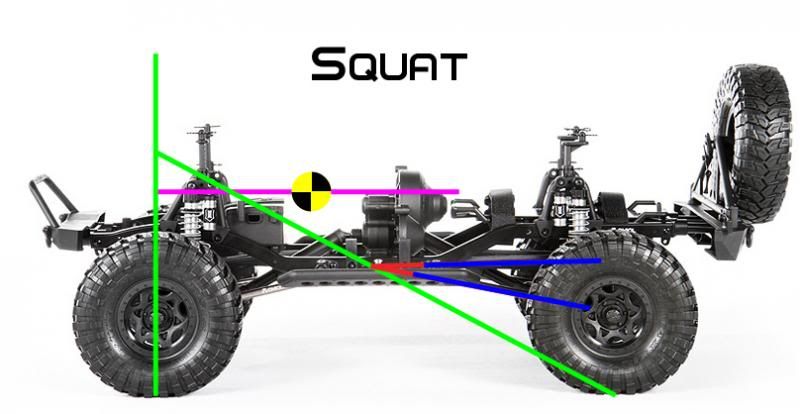

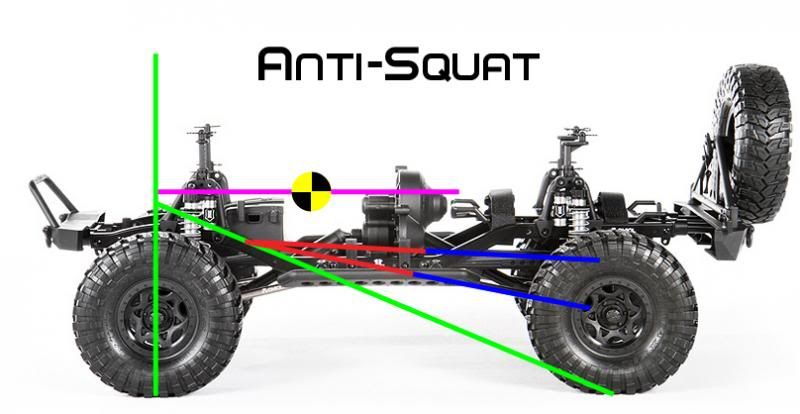

My input, from personal experience... Panhard should be exact same length as drag link. If you are off a little bit it's not a big deal, but will give some bump steer and off enough it will cause issues. "A Little Bit" would be something within 5-10% of length. You want these parallel to each other. You are basically creating a parallelogram and as the suspension cycles, the parallel parts need to stay that way to prevent bump steer. Proper geometry will keep everything in line. For the rear links, as was suggested, moving the front portion of the rear upper links is a good step. There are some theories to this, but geometry rules. Basically the way the stock SCX10 is setup is not horrible, but a little better separation of the front mounting points of the rear links will give better stability throughout the cycle. More geometry here. You want the separation in the front about the same as the back. There are some effects with squat and anti squat that will result by moving these points, but with a forward biased center of gravity, that separation allows better anti-squat depending on where your center of gravity is. The Stock SCX Suspension could lead to squat under load:  Since the line connecting the intersection of the links and the tire contact patch extended vertically above the front axle ends up above the center of gravity, the links act as a lever to lower the rear of the chassis. On a steep climb, this can make it easier for the front end to lift and flip the truck over. Adding separation to the links allows better anti-squat:  The intersecting line is below the center of gravity, so the links act as a lever to lift the rear of the chassis. On steep climbs the weight is pushed forward to try to keep the weight on the front wheels. Really, it depends on where your center of gravity ends up. (BTW, if the links are exactly parallel, there is no intersecting point, and no matter where your center of gravity is, the links will provide anti squat.) The above pics show with a fully sprung suspension. Doing a partial droop suspension (as well as generally throughout the suspension cycle) will affect the way everything acts. For droop, You are on the right track. A little compression is good to soak up bumps (even low-speed bumps) and the droop allows the tires to break over obstacles. I highly recommend something to keep the shocks sucked down to prevent unloading on vertical climbs and sidehills. Pen springs are easy to source, and easy to add into the shocks under the piston. This will limit travel a bit, but it looks like you were doing that anyway. Way back in the day (2009), I was running full droop with near parallel links on my shafty comp rig:  This set-up was stable and predictable, keeping the COG low and allowed for pretty steep climbs (for a shaft driven crawler). For a scale rig, you do want some compression to soak up bumps and falls though. Sorry for the long technical response, but I hope it helps figure out the suspension geometry issues you are having. I've been watching this build since the beginning when it was part of the build off. I love the design, and can't wait to see this all finished up and on the rocks/trails. Keep up the great work! |

| |  |

| | #138 |

| RCC Addict Join Date: Aug 2010 Location: wherever paypal sais.

Posts: 1,740

|

great info here!! realized my setup is all jacked. |

| |  |

| | #139 |

| I wanna be Dave Join Date: Jun 2008 Location: Sin City

Posts: 3,628

|

I think that is the best I have ever seen that worded MonkeyRacer.....  Just started a 3/4 link for Dummies thread - this is a subject I have wanted to discuss with others. A lot is how one person feels a rig out over another - What you notice and I dont. 3/4 link for Dummies |

| |  |

| | #140 |

| RCC Addict  Join Date: May 2010 Location: Midwest

Posts: 1,917

|

Alright.. I busted some ass today.. I needed somewhere for my servo winch to mount.. This is what underneath the passenger fender used to look..  and this is how it looks now...  A little artsy IMO but, I think I like it. I fabbed up some brackets for the servo to mount vertical with the spool facing forward.  Also.. I made a spool gaurd to keep the spool from getting damaged due to it's location..    with the hood on. the tires out front are a little forward in the well so, they should stay away from the spool guard pretty good. I'm gonna have to come up with a wheel liner or something to keep crap out of the winch.  I finished & dolled up my panhard mount..  I stuck on some tabs for mounting the sides of the hood/fender combo.. the tabs are those gearhead tabs that are like $1.00 each or whatever.. I gotta say.. they are worth the money. I haven't measured the hole in them but, they are supposed to be able to be tapped for M3. They aren't junky though.. pretty beefy.  Ok.. I got like an hour into making this tiny little "winch line tunnel guide"..   ........ |

| |  |

|

Die-Laughing's Class2 Ultra4 Jeep! - Similar Threads

Die-Laughing's Class2 Ultra4 Jeep! - Similar Threads | ||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Die-Laughing's 2.2 Sledge Hammer!! | Die-Laughing | 2.2 Scale Rigs | 50 | 06-29-2013 12:52 PM |

| Die-Laughing's Jeep YJ Hardtop... | Die-Laughing | 1.5 Scale Rigs | 33 | 02-06-2013 07:23 PM |

| Die-Laughing's Monster Truck.. | Die-Laughing | Axial Wraith | 16 | 02-06-2013 06:27 PM |

| Die-Laughing's BadAss FJ | Die-Laughing | 1.9 Scale Rigs | 89 | 09-28-2012 01:59 PM |

| Die-Laughing's Wrecktuber | Die-Laughing | 2.2 Scale Rigs | 78 | 02-26-2012 09:54 PM |

| |